The Versatile 87740 Motor

The 87740 motor is the driving force behind some of the most popular pipe threaders in the industry, including the RIDGID® 300 and 535. The Steel Dragon Tools version of the 87740 motor powers the Steel Dragon Tools 300 and 7090i. The 87740 motor is a versatile work horse and can be used across a variety of platforms thanks to interchangeable gearboxes. This motor is reliable, durable, and easy to service should the need ever arise.

The 87740 motor has three main components; the field, the armature, and brushes.

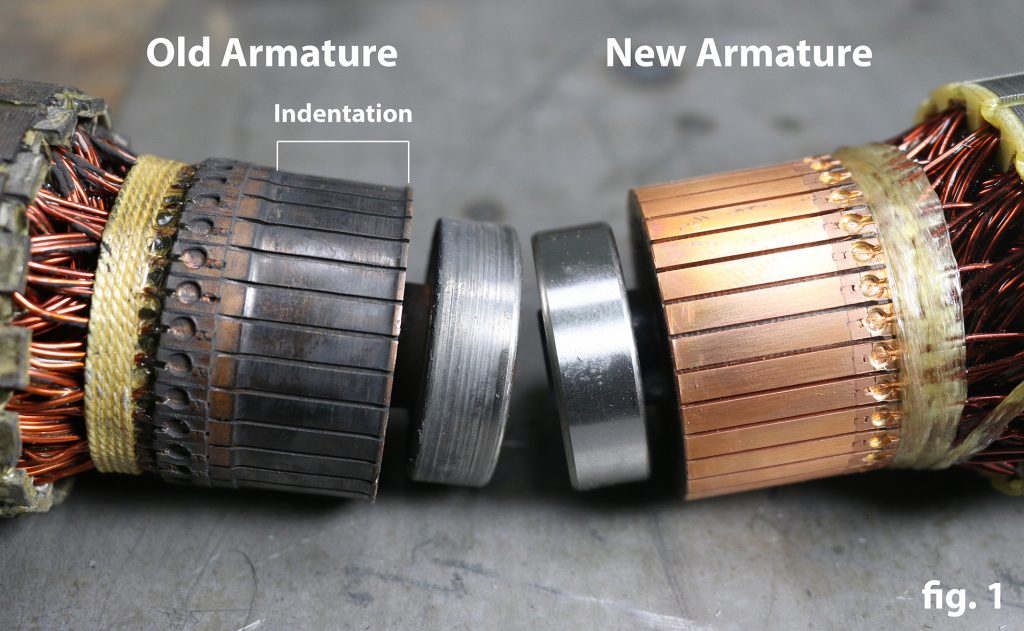

The brushes are the item most likely to wear out first. The brushes are designed to make constant contact with the commutator of the armature. While the brushes are considered a wear item to be replaced on occasion, it is also important to inspect the armature and especially the commutator. After many years of use, the commutator can be worn away due to the constant contact with the motor brushes. This wear will result in a slight indentation in the commutator (fig. 1). New brushes will not be able to make solid, constant contact with the commutator, resulting in sparking, higher current draw, and loss of power. If the commutator shows this type of wear, it is easier and more cost effective to replace the entire armature.

The motor field is not a wear piece and will rarely need to be replaced unless it is damaged. Damage is most likely to occur during operation or maintenance. The field can be damaged by an electrical surge or if an internal wire is pinched.

Steel Dragon Tools offers replacement parts that will fit any 87740 model. Steel Dragon Tools is also a full-service repair shop specializing in reconditioning pipe threading machines. Steel Dragon Tools technicians have decades of experience and can quickly diagnose and repair most 87740 motors.

For more information on Steel Dragon Tools call 734-224-7112 or e-mail customer service here.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon, Sears, and Walmart.

We are not an authorized distributor of RIDGID® and/or Ridge products. RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

Tools repaired and reconditioned by Steel Dragon Tools voids original warranties and certifications from Ridge Tool.

Steel Dragon Tools is always looking for used or broken pipe threading machines and pipe threading accessories. Click here for the purchase list and prices.

Obscure Fact About the 535

Steel Dragon Tools has over a decade of experience refurbishing pipe threading machines and accessories. The RIDGID® 535 is a prime candidate for reconditioning and can be found quite often in the Steel Dragon Tools shop. The 535 debuted on the market in 1957 and has been running in one form or another for over 50 years. Despite the years of experience, the technicians in the Steel Dragon Tools shop are always learning something new. In this case, the technicians pointed out that an 815A die head is not compatible on a 535 Version 1 machines that is equipped with a 340 Reamer.

This is a very specific issue that won’t affect most customers who use a 535 Version 1 machine. While the 815A die head is compatible with the 535, most customers will use the 811A die head. The 811A die head is much more common and is included with all reconditioned RIDGID® 535 packages offered by Steel Dragon Tools. For customers who have a 535 Version 1 machine and want to use an 815A die head, be sure to check which reamer in on the machine.

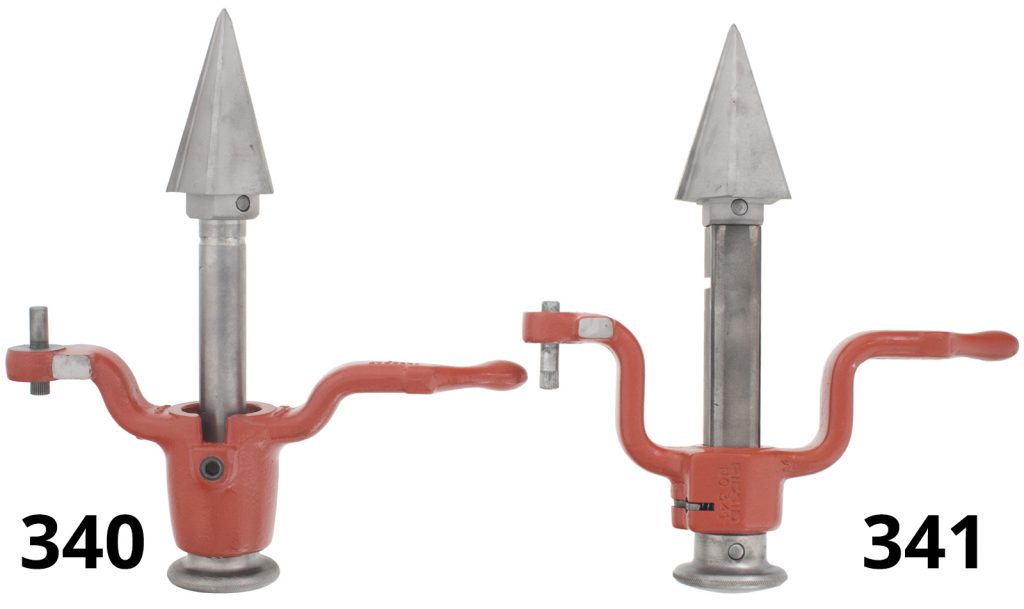

Over the years, as the 535 machine changed from Version 1 to Version 2 to Version 3, the attachments changed slightly as well. The 811 die head became the 811A die head and allowed for automatic oiling. The 815A die head was later introduced with an automatic opening feature that opens the die head when threading is complete. The 340 reamer was updated slightly to become the 341 reamer.

The 341 reamer is standard on later model 535 machines but will also fit the original 535 design. The difference between the 340 and 341 is nominal. The only thing that has changed over 50 years is the shape of the reamer arm. The 341 reamer has a shallow arm while the 340 reamer has a much more pronounced arm. It is the arm of the 340 reamer that will contact the 815A die head trigger, preventing the reamer from raising or lowering on the machine. This is only an issue when using an 815A die head on a RIDGID® 535 Version 1 machine that is equipped with a 340 reamer.

To learn more about Steel Dragon Tools reconditioned RIDGID® 535 machines, click here.

To learn about the difference between 811 and 815 die heads, click here.

For more information on Steel Dragon Tools call 734-224-7112 or e-mail customer service here.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon, Sears, and Walmart.

Steel Dragon Tools is always looking for used or broken pipe threading machines and pipe threading accessories. Click here for the purchase list and prices.

We are not an authorized distributor of RIDGID® and/or Ridge products. RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

Wire Strippers – WRA 10 vs WRA 15

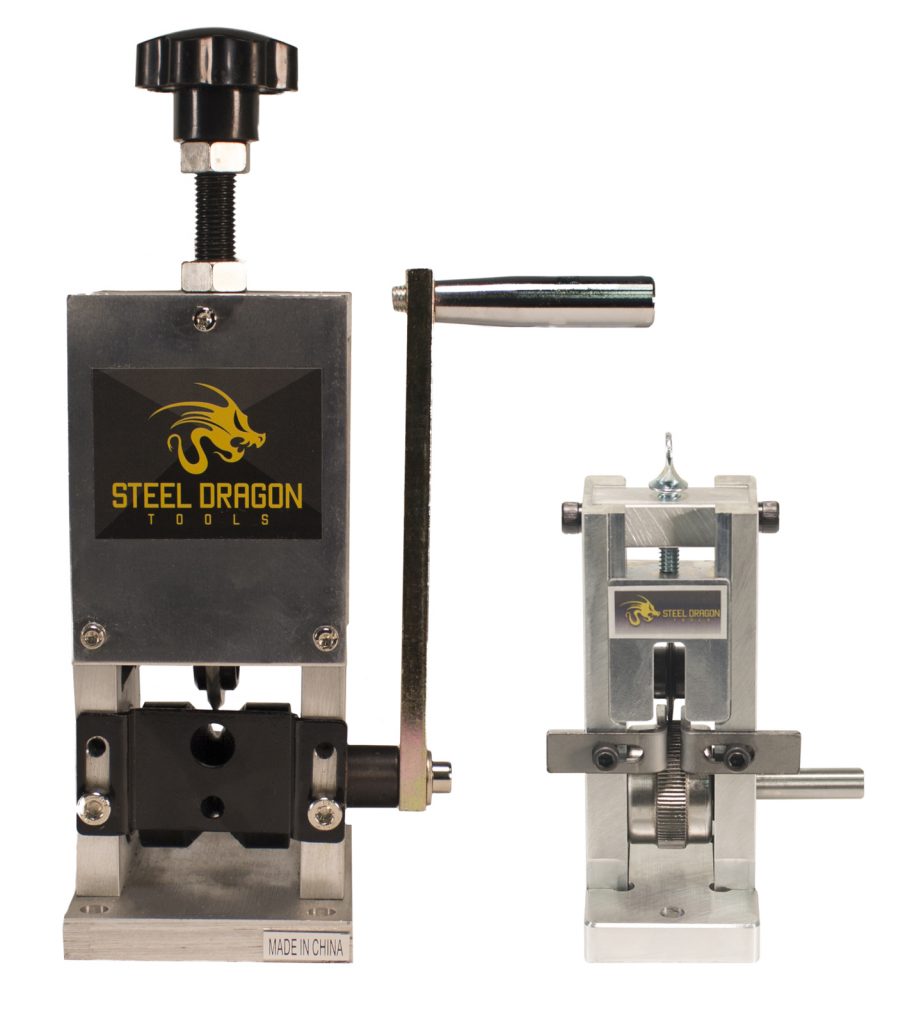

Steel Dragon Tools offers several different models of wire strippers. The two entry level options are the WRA10 and the WRA15. Both models can be operated manually with a hand crank or automatically with a drill. The WRA10 and WRA15 are an ideal entry point for anyone looking to strip wire and increase recycling payouts on scrap metal.

The WRA10 is small, at 6-inches in height it is almost pocket size. But behind the diminutive size is an easy to operate machine that will quickly and cleanly strip up to 450 inches of wire per minute when connected to a drill. The WRA10 will strip wire up to roughly 1/2-inch in diameter.

The WRA15 is the more traditional benchtop model. It boasts a larger size and wire-stripping capability. Standing at 12-1/2-inches in height it will also strip up to 450 inches of wire per minute when connected to a drill. The WRA15 will strip wire up to roughly 1-inch in diameter.

Set Up is Key

Set up is the most important step to successfully strip wire. Following these tips will help make the wire stripping process quick and easy. These tips apply to both the WRA10 and WRA15.

- Secure the wire stripper to the benchtop. Screwing or bolting the wire stripper to the bench will stop it from moving during the stripping process, freeing the hands to feed the wire and operate the drill at the same time.

- Separate wire by size, set machine to strip that size, and then strip all of that wire at once. Getting the wire stripper keyed in to quickly strip the wire requires careful set up. Strip one size at a time before moving on to avoid wasting time readjusting between each piece.

- Do not run the drill at full speed. A common mistake is to run the drill as fast as possible. Typically, this will result in a wire that isn’t completely stripped as well as reducing the life of the cutting wheel.

- Run the drill slowly and at an even pace. The same applies when using the hand crank.

- Run the wire through twice. The WRA10 and WRA15 only have one cutting wheel. Run the wire through once and then rotate it 180 degrees before running it through again. Two cuts in the casing will make stripping the wire much easier.

- Straighten the wire and cut it into manageable pieces between 12-inches and 24-inches in length. A straight piece of wire has little chance of bunching up and clogging the machine. A short piece of wire will run through the machine quickly, especially if the operator wants to run it through twice.

- Running long pieces of wire can pose a safety hazard. This warning applies to the larger machines but the principle is still the same. When running long pieces of wire can be dangerous as the wire may become wrapped around the operator or other nearby objects. The operator or these objects can then be pulled toward the wire stripper if enough force is being generated.

For more information on Steel Dragon Tools call 734-224-7112 or e-mail customerservice@steeldragontools.com.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon, Sears, and Walmart.

Comparing 4″ Pipe Threaders

Steel Dragon Tools offers two models of pipe threading machines that thread, cut and ream up to 4-inch pipe, rod, and bolts. The Steel Dragon Tools 1224 and the Steel Dragon Tools 6790 pipe threading machines both thread, cut, and ream a wide range of black, galvanized, and plastic-coated pipe, as well as stainless steel, IMC, and heavy-wall conduit. Both machines are equipped with a foot switch, reversible motor, and come with die heads and dies, and an optional stand. The Steel Dragon Tools 6790 has a threading range of 1/2 in. to 4 in. The Steel Dragon Tools 1224 has a threading range of 1/4 in. to 4 in.

There are four major difference between the 1224 and the 6790:

1: The Steel Dragon Tools 1224 is compatible with universal RIDGID® brand dies, die heads, and jaw inserts. RIDGID® or Steel Dragon Tools 711 and 714 die heads are interchangeable between the Steel Dragon Tools 1224 and the RIDGID® 1224 pipe threading machines. All universal dies will fit both die heads and machines. The Steel Dragon Tools 1224 comes with a Steel Dragon Tools 711 and Steel Dragon Tools 714 die head. The Steel Dragon Tools 6790 pipe threading machine also includes two die heads but the dies and die heads for the 6790 will only fit other compatible Steel Dragon Tools pipe threaders.

2: The Steel Dragon Tools 1224 pipe threading machine is adjustable to thread both NPT (National Pipe Thread Tape) and NPSM (National Pipe Straight Mechanical) threads. The 6790 only threads NPT. The ability of the 1224 to thread both NPT and NPSM makes it an easy choice for electrical contractors who may have to do both.

3: The Steel Dragon Tools 6790 pipe threading machine has a two-speed transmission and 750-watt induction motor. The Steel Dragon Tools 1224 has a three-speed transmission and a 1,500-watt motor. The 1224 will handle 4-inch pipe threading much easier than the 6790 due to a larger motor motor and more-powerful transmission.

4: Price. The Steel Dragon Tools 1224 is considerably more expensive than the Steel Dragon Tools 6790. Both machines, however, cost significantly less than other machines built but name-brand competitors.

Click here to learn more about the importance of pipe threading oil.

For more information on Steel Dragon Tools call 734-224-7112 or e-mail customerservice@steeldragontools.com.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon, Sears, and Walmart.

RIDGID® marks are trademarks of RIDGID, Inc and are used only for product identification purposes.

“A” is for Automatic – 811A and 815A

Die heads for most Steel Dragon Tools and RIDGID® power pipe threading machines will either be automatic or non-automatic. Automatic refers the die head’s ability to automatically oil the pipe during the pipe threading process. These die heads will have a through-head oiling system. Automatic die heads will also have an “A” designation in their name like 811A or 815A.

The die head will connect to the pipe threading machine’s oil reservoir, if the machine has one (Steel Dragon Tools and RIDGID® 300 Power Drives do not have an oil reservoir and require a separate, manually operated oiler – like the Steel Dragon Tools 418 Oiler).

A pump in the pipe threading machine will push pipe threading oil to the die head where it will be distributed over the pipe during the pipe threading process. The automatic-style die head is now used across the industry. Non-automatic 811 and 815 die heads are typically not sold as new but can be found used or reconditioned. Steel Dragon Tools buys and reconditions used and broken pipe threading machines and accessories, including RIDGID® 811, 811A, 815, and 815A die heads.

Click here for more information on selling used equipment to Steel Dragon Tools.

Click here to learn more about the importance of pipe threading oil.

Click here to learn more about the difference between 811 and 815 die heads.

For more information on Steel Dragon Tools call 734-224-7112 or e-mail customerservice@steeldragontools.com.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon, Sears, and Walmart.

RIDGID® marks are trademarks of RIDGID, Inc and are used only for product identification purposes.

811 vs 815 Die Head Debate

A die head (or two) is a requirement for most industry-standard pipe threading machines. Using a Steel Dragon Tools 300, 300C, 7090-PRO, 7090i, 7090e, or a RIDGID® 300, 300A, 500A, 535, 535A, 800, 801, 802, or 1822 pipe threading machine will require a die head. Pipe threading professionals can choose between the 811- or the 815-style die head. (Most 811- and 815-style die heads are now being manufactured with automatic oiling operation, designated by the letter A — more on this next week.)

A die head (or two) is a requirement for most industry-standard pipe threading machines. Using a Steel Dragon Tools 300, 300C, 7090-PRO, 7090i, 7090e, or a RIDGID® 300, 300A, 500A, 535, 535A, 800, 801, 802, or 1822 pipe threading machine will require a die head. Pipe threading professionals can choose between the 811- or the 815-style die head. (Most 811- and 815-style die heads are now being manufactured with automatic oiling operation, designated by the letter A — more on this next week.)

The main difference between the 811 and the 815 comes in operation. The 815 die head has a trigger mechanism that will automatically open the die head and stop the threading process once a certain number of threads have been cut. The 811 die head has a quick open lever that must be opened manually to stop the pipe threading process. Both die heads can be used to thread pipe and bolts, both thread in the right-hand direction, and both have the same threading capacities.

Seems like an easy choice, right? However, the 811 die head allows for a flexibility in threading that the 815 cannot accommodate. The 815 die head will always cut the same number of threads per pipe size before the pipe hits the trigger and stops the threading process. The 811 die head can thread further down the pipe should the need arise.

The 811 die head will also be more reliable in the long run since there are no extra mechanical pieces to break or malfunction. Price-wise, the 815 will be slightly more expensive than the 811 but not by much.

Steel Dragon Tools manufactures an 811A and 815A die head that will fit most industry standard pipe threading machines including Steel Dragon Tools and RIDGID® machines. Steel Dragon Tools 811A and 815A die heads are offered with an automatic oiling feature for use on pipe threading machines that have a pipe threading oil reservoir.

For more information on Steel Dragon Tools call 734-224-7112 or e-mail customerservice@steeldragontools.com.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon, Sears, and Walmart.

Steel Dragon Tools is always looking for used or broken pipe threading machines and pipe threading accessories. Click here for the purchase list and prices.

We are not an authorized distributor of RIDGID® and/or Ridge products. RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

Reconditioned RIDGID® 300

The Steel Dragon Tools Reconditioned RIDGID® 300 is a versatile power drive that can be used for pipe threading or roll grooving applications. Steel Dragon Tools is an industry leader in reconditioning and refurbishing used or broken pipe threading machines and pipe threading accessories. Each machine is disassembled, degreased, cleaned, painted, reassembled. All reconditioned machines from Steel Dragon Tools are backed by a one (1) year warranty against manufacturer defect.

The Steel Dragon Tools Reconditioned RIDGID® 300 is a versatile power drive that can be used for pipe threading or roll grooving applications. Steel Dragon Tools is an industry leader in reconditioning and refurbishing used or broken pipe threading machines and pipe threading accessories. Each machine is disassembled, degreased, cleaned, painted, reassembled. All reconditioned machines from Steel Dragon Tools are backed by a one (1) year warranty against manufacturer defect.

Steel Dragon Tools offers the reconditioned RIDGID® 300 in several different packages. Customers can choose a package that will meet their needs. Packages include pipe threading machines with extra dies, extra die heads, or pipe threading oil.

Packages are available with either reconditioned RIDGID® accessories or Steel Dragon Tools accessories. These accessories include an 811A die head, universal high-speed dies, 360 pipe cutter, 341 pipe reamer, 311 carriage, 1206 stand, and 418 oiler bucket.

The reconditioned RIDGID® 300 is equipped with a foot pedal for hands-free operation and has a pipe threading capacity of 1/4-inch pipe to 2-inch pipe.

The reconditioned RIDGID® 300 can also be used for roll grooving with a compatible roll-grooving attachment. All reconditioned RIDGID® 300 pipe threading machines are compatible with RIDGID® and Steel Dragon Tool accessories and replacement parts.

For more information on Steel Dragon Tools call 734-224-7112 or e-mail customerservice@steeldragontools.com.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon, Sears, and Walmart.

Steel Dragon Tools is always looking for used or broken pipe threading machines and pipe threading accessories. Click here for the purchase list and prices.

We are not an authorized distributor of RIDGID® and/or Ridge products. RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

Tools repaired and reconditioned by Steel Dragon Tools voids original warranties and certifications from Ridge Tool.