Obscure Fact About the 535

Steel Dragon Tools has over a decade of experience refurbishing pipe threading machines and accessories. The RIDGID® 535 is a prime candidate for reconditioning and can be found quite often in the Steel Dragon Tools shop. The 535 debuted on the market in 1957 and has been running in one form or another for over 50 years. Despite the years of experience, the technicians in the Steel Dragon Tools shop are always learning something new. In this case, the technicians pointed out that an 815A die head is not compatible on a 535 Version 1 machines that is equipped with a 340 Reamer.

This is a very specific issue that won’t affect most customers who use a 535 Version 1 machine. While the 815A die head is compatible with the 535, most customers will use the 811A die head. The 811A die head is much more common and is included with all reconditioned RIDGID® 535 packages offered by Steel Dragon Tools. For customers who have a 535 Version 1 machine and want to use an 815A die head, be sure to check which reamer in on the machine.

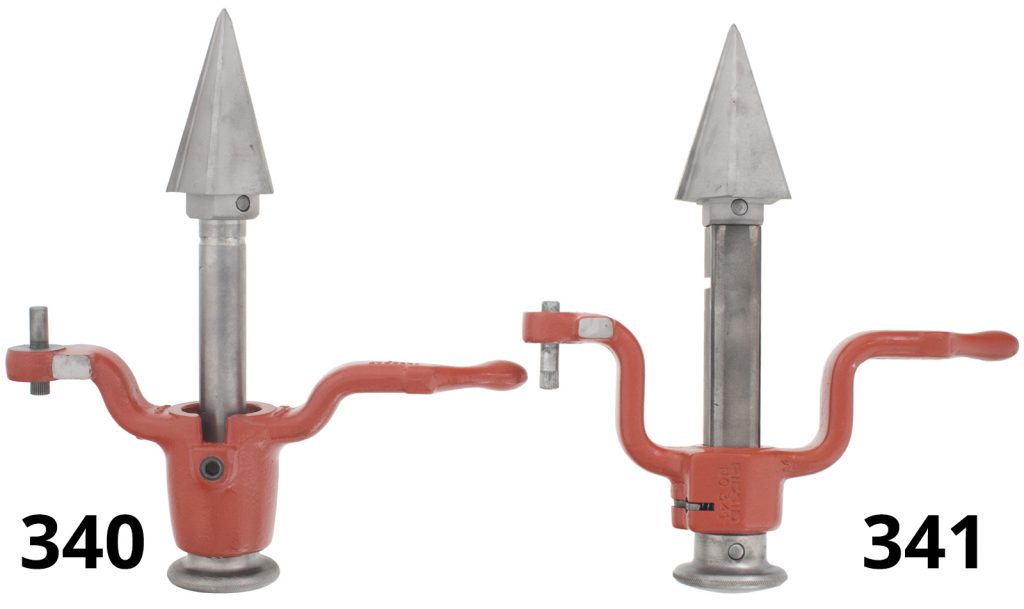

Over the years, as the 535 machine changed from Version 1 to Version 2 to Version 3, the attachments changed slightly as well. The 811 die head became the 811A die head and allowed for automatic oiling. The 815A die head was later introduced with an automatic opening feature that opens the die head when threading is complete. The 340 reamer was updated slightly to become the 341 reamer.

The 341 reamer is standard on later model 535 machines but will also fit the original 535 design. The difference between the 340 and 341 is nominal. The only thing that has changed over 50 years is the shape of the reamer arm. The 341 reamer has a shallow arm while the 340 reamer has a much more pronounced arm. It is the arm of the 340 reamer that will contact the 815A die head trigger, preventing the reamer from raising or lowering on the machine. This is only an issue when using an 815A die head on a RIDGID® 535 Version 1 machine that is equipped with a 340 reamer.

To learn more about Steel Dragon Tools reconditioned RIDGID® 535 machines, click here.

To learn about the difference between 811 and 815 die heads, click here.

For more information on Steel Dragon Tools call 734-224-7112 or e-mail customer service here.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon, Sears, and Walmart.

Steel Dragon Tools is always looking for used or broken pipe threading machines and pipe threading accessories. Click here for the purchase list and prices.

We are not an authorized distributor of RIDGID® and/or Ridge products. RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

Wire Strippers – WRA 10 vs WRA 15

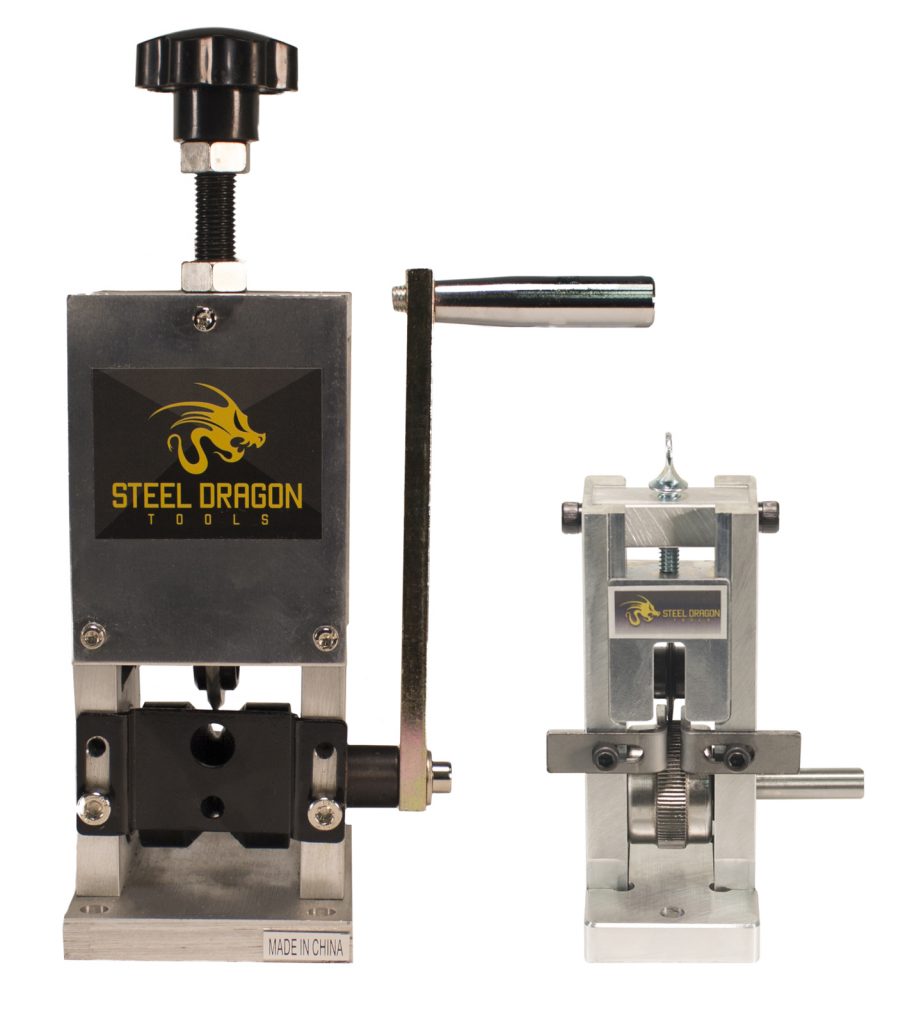

Steel Dragon Tools offers several different models of wire strippers. The two entry level options are the WRA10 and the WRA15. Both models can be operated manually with a hand crank or automatically with a drill. The WRA10 and WRA15 are an ideal entry point for anyone looking to strip wire and increase recycling payouts on scrap metal.

The WRA10 is small, at 6-inches in height it is almost pocket size. But behind the diminutive size is an easy to operate machine that will quickly and cleanly strip up to 450 inches of wire per minute when connected to a drill. The WRA10 will strip wire up to roughly 1/2-inch in diameter.

The WRA15 is the more traditional benchtop model. It boasts a larger size and wire-stripping capability. Standing at 12-1/2-inches in height it will also strip up to 450 inches of wire per minute when connected to a drill. The WRA15 will strip wire up to roughly 1-inch in diameter.

Set Up is Key

Set up is the most important step to successfully strip wire. Following these tips will help make the wire stripping process quick and easy. These tips apply to both the WRA10 and WRA15.

- Secure the wire stripper to the benchtop. Screwing or bolting the wire stripper to the bench will stop it from moving during the stripping process, freeing the hands to feed the wire and operate the drill at the same time.

- Separate wire by size, set machine to strip that size, and then strip all of that wire at once. Getting the wire stripper keyed in to quickly strip the wire requires careful set up. Strip one size at a time before moving on to avoid wasting time readjusting between each piece.

- Do not run the drill at full speed. A common mistake is to run the drill as fast as possible. Typically, this will result in a wire that isn’t completely stripped as well as reducing the life of the cutting wheel.

- Run the drill slowly and at an even pace. The same applies when using the hand crank.

- Run the wire through twice. The WRA10 and WRA15 only have one cutting wheel. Run the wire through once and then rotate it 180 degrees before running it through again. Two cuts in the casing will make stripping the wire much easier.

- Straighten the wire and cut it into manageable pieces between 12-inches and 24-inches in length. A straight piece of wire has little chance of bunching up and clogging the machine. A short piece of wire will run through the machine quickly, especially if the operator wants to run it through twice.

- Running long pieces of wire can pose a safety hazard. This warning applies to the larger machines but the principle is still the same. When running long pieces of wire can be dangerous as the wire may become wrapped around the operator or other nearby objects. The operator or these objects can then be pulled toward the wire stripper if enough force is being generated.

For more information on Steel Dragon Tools call 734-224-7112 or e-mail customerservice@steeldragontools.com.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon, Sears, and Walmart.

Reconditioning Pipe Threaders – The Process Part 1

The process starts when Steel Dragon Tools buys a used pipe threading machine. Steel Dragon Tools will buy a variety of models as well as the accessories. For more information on selling a used pipe threading machine, please click here.

Steel Dragon Tools actively seeks out used or broken machines for repair. Shop manager David Krell searches Craigslist, eBay, and other internet forums and classifieds to find these used machines. Steel Dragon Tools can arrange for shipping. After working out a deal with the seller, these machines are brought into the shop to be refurbished.

The used machines are brought into the shop and disassembled. All pieces are examined to determine condition. Parts in poor condition will be replaced to ensure safety and effective operation. All wear items, including motor field, brushes, and armatures, as well as gears, bearings, and power cord will be inspected and replaced as needed.

Steel Dragon Tools also offers repair service for many of the most popular pipe threading machines on the market. Along with repair shop, Steel Dragon Tools also manufactures a wide variety of industrial tools including a full line of pipe threading machines die heads, dies, and replacement parts that will fit many of the industry-standard machines. Steel Dragon Tools also manufactures cable wire hoists, core drill rigs, drain cleaning machines, lifting magnets, annular cutters, and pipe inspection cameras. To view a full list of Steel Dragon Tools products, please click here.

For more information about Steel Dragon Tools please call contact Customer Service at 734-224-7112 or by e-mail here.

Steel Dragon Tools is not an authorized distributor of RIDGID® and/or Ridge products. RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

The Art of Active Listening

By Samantha Benson, Customer Service Manager at Steel Dragon Tools

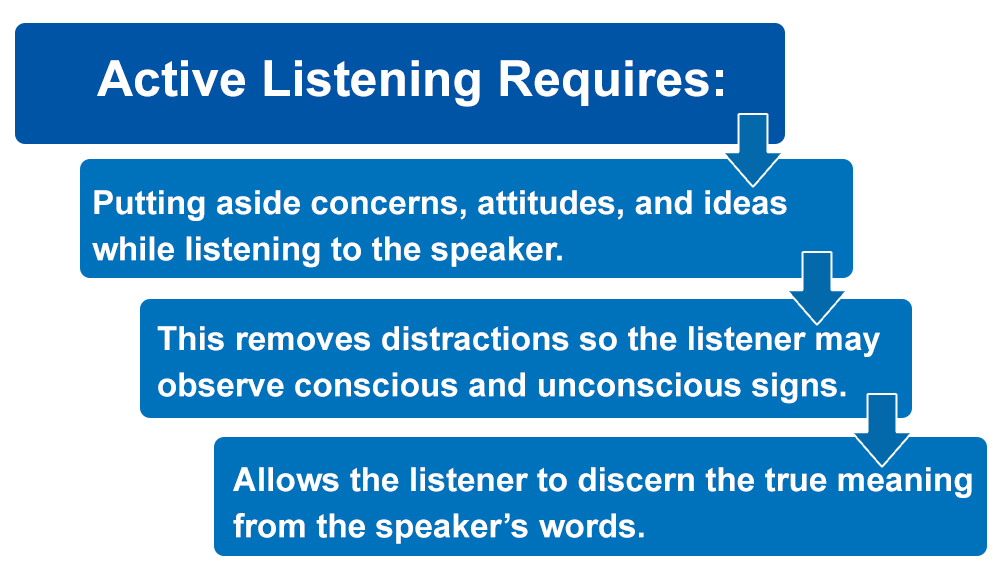

The customer service representative at Steel Dragon Tools have all been trained to be active listeners. Active listening is a way of communicating with another person to improve mutual understanding. Sometimes, when two people are talking to each other, one or both may not be actively listening, they may be distracted or simply waiting for the other person to finish so they can speak.

Below are some active listening techniques that we use to help our customer service representative become better communicators. These techniques work well in the realm of customer service but can be applied in any situation to help us understand each other better and improve our daily relationships.

Active Listening in Every Situation

Do:

- Paraphrase the speaker’s words.

- Be mentally prepared to listen.

- Evaluate the speech, not the speaker.

- Be unbiased toward the speaker by depersonalizing and stepping away from emotional response.

- Fight distractions by tuning out external sounds.

- Ask questions to clarify and corroborate thoughts.

Don’t:

- Show boredom.

- Get distracted by outside stimuli.

- Prepare your response or mentally argue while the speaker is talking.

- Interrupt the speaker.

- Reflex on the rightness or wrongness of what is being said.

This is the second part of the article Communicating for Success. To view the first part of the article, click here.

Steel Dragon Tools customer service can be contacted by e-mail or by phone at 734-224-7112.

Dies from Steel Dragon Tools

Steel Dragon Tools manufactures high speed steel and alloy dies to meet or exceed industry specifications. These dies are compatible with Steel Dragon Tools pipe threading machines and can be used in compatible dies heads with other machine brands.

Dies are an essential part of the pipe threading process. Sharp, well-made dies will ensure consistent, useable threads. Dies with dull or chipped teeth will result in poorly threaded pipe that will not seal properly. Replacing dies as they wear or chip is a necessity but it doesn’t have to break the bank.

Steel Dragon Tools dies are compatible with the specified Steel Dragon Tools pipe threaders and will fit certain other brands. Steel Dragon Tools dies will match the quality of comparable dies but for a fraction of the price. Steel Dragon Tools can offer dies for far less since there is no middle man. Steel Dragon Tools manufacturers the dies and then sells them directly to the customer. Buy an extra set of dies and never worry about chipping a tooth while on the job site.

Steel Dragon Tools manufactures dies for powered and manual pipe threading machines. Many of these dies can be used in compatible die heads from Wheeler Rex® and RIDGID® machines.

For more information on the Steel Dragon Tools dies, click here. For more information on Steel Dragon Tools pipe threading machines, click here.

For more information about Steel Dragon Tools please call contact Customer Service at 734-224-7112 or by e-mail here.

The full line of Steel Dragon Tools are available for purchase from Craig’s Affordable Tools or Toolz Unlimited.

We are not an authorized distributor of RIDGID® and/or Ridge products. RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

Steel Dragon Tools Buys Used Equipment

Steel Dragon Tools will buy used and broken pipe threading machines and accessories. Steel Dragon Tools has ten years of experience refurbishing pipe threading machines and is always looking for items to refurbish.

Steel Dragon Tools will buy the following machines:

| MANUFACTURER | MODEL | |

|---|---|---|

| RIDGID® | 300 Power Drive | |

| RIDGID® | 300 Power Drive with Stand | |

| RIDGID® | 300 Power Drive with Stand, Carriage, Die Head, Cutter, Reamer | |

| RIDGID® | 811A and 815A Universal Die Heads | |

| RIDGID® | 811 and 815 Universal Die Heads (older models) | |

| RIDGID® | 141 with dies in good condition | |

| RIDGID® | 161 with dies in good condition | |

| RIDGID® | 1224 Pipe Threader | |

| RIDGID® | 535 Pipe Threader (Old Style) with die head | |

| RIDGID® | 535 Pipe Threader (New Style) with die head | |

| RIDGID® | 535M Pipe Threader | |

| RIDGID® | 1822 Pipe Threader | |

| RIDGID® | 300C Pipe Threader | |

| RIDGID® | 700 Power Drive | |

| RIDGID® | 12R Die Heads | |

| RIDGID® | 42620 Model 774 Square Drive Adapter | |

| RIDGID® | 42405 844 Drive Bar for 141/161 geared pipe threaders | |

| RIDGID® | 19366 758 Loop for 141/161 geared pipe threaders | |

| RIDGID® | 40A TRISTAND® | |

| RIDGID® | 460 TRISTAND® |

All prices will vary depending on machine condition and current inventory.

Reduced prices will be offered for machines with cracked or missing feet, missing front chuck, etc.

Please send photos and contact information to: apietszak@steeldragontools.com or call 734-224-7112.

RIDGID® marks are trademarks of RIDGID, Inc and are used only for product identification purposes.

Best Practices to Ensure High-Quality Products

Steel Dragon Tools has built a reputation manufacturing quality tools and machines while pricing them to beat the competition. Setting forth and following best practices ensures that every product from Steel Dragon Tools meets or exceeds customer expectations and any applicable regulations. Steel Dragon Tools best practices include:

- All Steel Dragon Tools are CE Approved and government tested.

- An on-staff master technician inspects all Steel Dragon Tools to ensure top-of-the-line performance.

- Live, on-site customer service representatives provide valuable product knowledge. Customer service representatives are available to answer questions or offer technical

assistance on Steel Dragon Tools. Customer service representatives can be reached Monday through Friday, 8:00 a.m. to 6:00 p.m. EST at 734-224-7112. - All products manufactured by Steel Dragon Tools are backed by a one year warranty against manufacturer defects.

For more information on Steel Dragon Tools contact customer service here or by phone at 734-224-7112.

Steel Dragon Tools are available for purchase from AffordableTool.com and ToolzUnlimited.com.

Communicating For Success

By Samantha Benson – Customer Service Manager at Steel Dragon Tools

As a growing company, we like to do everything within our power to help the customers and make sure they are receiving the best service possible. We have worked for many years to increase our customer contact and we have succeeded in making our customer service stand out from the competition.

When calling Steel Dragon Tools, customers will not be met with an automated answering service or computer recording. A live, friendly customer service representative will assist with any questions or issues — from technical help to filing a return. Steel Dragon Tools has a same day response time that ensures that customers are being serviced in a timely manner and that all issues are resolved as quickly as possible.

Here at Steel Dragon Tools we believe communication makes or breaks relationships. We go the extra mile to make sure that our customer service team has received proper communication training. This training has helped to make the resolution time faster for customers and the conversations more enjoyable.

With these values in mind we are always looking at ways to improve our procedures and customer experiences. One of the best ways to get ideas for growth is directly from the customers. We follow up on all sales to make sure that you are happy with the product as well as the experience.

Every part of the transaction is important — from product detail in the description down to the packing when shipping the item. We want to make sure your voice is heard. Give us a call today and let us know what we can do to help.

Steel Dragon Tools customer service can be contacted by e-mail or by phone at 734-224-7112.