Making Pipe Dies Last

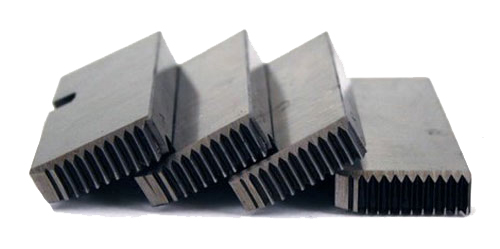

Quality pipe threading dies should last a very long time if care is taken to keep them in good working order. Steel Dragon Tools manufacturers dies that are compatible with several brand-name die heads and pipe threading machines. Steel Dragon Tools dies are made from a composite alloy or high-speed steel and, under proper working conditions, should last a very long time.

Quality pipe threading dies should last a very long time if care is taken to keep them in good working order. Steel Dragon Tools manufacturers dies that are compatible with several brand-name die heads and pipe threading machines. Steel Dragon Tools dies are made from a composite alloy or high-speed steel and, under proper working conditions, should last a very long time.

To get the most out of a set of Steel Dragon Tools dies, here are some important tips to keep in mind when threading pipe. The following tips should be applied to powered and manual pipe threading machines.

- Always use a high-quality pipe threading oil. High-quality pipe threading oil will reduce the friction between the dies and the pipe. The oil will also absorb heat during the threading process. Excess heat during the threading process can damage the dies and the pipe. Excess heat can cause metal chips to become welded to the dies. Metal chips in the die teeth will affect the consistency and shape of the threads.

- Keep the dies clean. Clean dies make for clean threads. After threading pipe, use a stiff-bristle wire brush to clean any debris that may be stuck in the die teeth.

- Install the dies properly into the die head. Dies that are not properly installed can result in damage to both the die teeth and the pipe. Double check to make sure the dies are properly installed before threading pipe.

Following these steps will help ensure that the Steel Dragon Tools dies enjoy a long operating life and provide you with many perfectly threaded pipes.

To view Steel Dragon Tools dies, click here.

For more information on the Steel Dragon Tools dies call 734-224-7112 or e-mail customerservice@steeldragontools.com.

Learn more about the importance of pipe threading oil.

Learn more about installing dies into die heads.

Learn more about Steel Dragon Tools die heads.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon and Walmart.

Tips and Tricks for the 535

One of the common complaints from users of the Steel Dragon Tools Reconditioned RIDGID® 535 is that the chuck or the pipe wobbles, resulting in unusable threads.

If the machine is not threading properly, check the dies first. A good set of dies should last a very long time. Unless the die teeth are chipped or otherwise damaged, the dies should work without issue. Next, check the installation. Dies will fit into the die head only one way but should be installed securely and in the proper order. If the dies are installed properly, check the rear centering chuck. The rear centering chuck simply keeps the pipe centered in the machine. Do not over tighten the rear chuck. Only hand tighten the rear chuck, do not use tools.

The front chuck does most of the work when threading pipe. The front chuck should only be hand tightened. Do not use tools to tighten the front chucks.

To tighten front and rear chuck, spin chuck forcefully in a counter clockwise motion. The chuck will tighten around the pipe. Do this several times to ensure a snug fit. The sound the that the chuck makes will change as it tightens. Once the sound changes, the chuck is tight. A tightened chuck will give off a short, dull sound as the chuck has already tightened around the pipe.

Other Tips to Remember:

The guide marks on the die head are not exact. Always run a simple threading test before threading the actual work piece. Use a properly-sized fitting to test the threads. A properly threaded pipe will allow the fitting to turn one and a half to two turns before meeting any resistance. If the fitting continues to turn easily or does not turn at all, the die head settings will need to be adjusted.

Threads should only be cut to the width of the die head. Cutting threads too far down the pipe may result in unusable threads. Some dies are designed to cut tapered threads. Cutting beyond the width of the die head will result in straight threads instead of the desired tapered threads.

For more information about Steel Dragon Tools please call contact Customer Service at 734-224-7112 or by e-mail here.

RIDGID® marks are trademarks of RIDGID, Inc and are used only for product identification purposes.

Pipe Abbreviations

As with any profession, there can be lots of arcane abbreviations and jargon – pipe threading is no different. Steel Dragon Tools is committed to educating customers and helping them make informed decisions. Buying a new pipe threader from Steel Dragon Tools may have been the easy part, but trying to figure pipe nomenclature can be downright confusing. For anyone new to the industry, or for veterans looking for a quick refresher, here is how to make sense of pipe nomenclature.

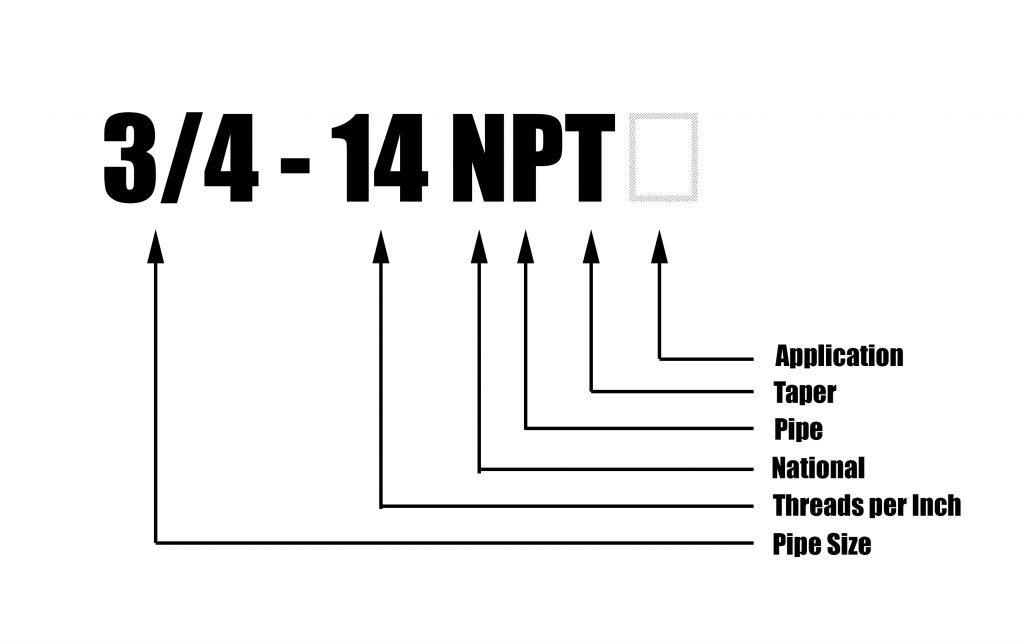

American National Standard Pipe Thread standards are always represented as a string of numbers and letters. Pipe nomenclature will look like this: 3/4 – 14 NPTG. All numbers and letters stand for something and are important to understand the pipe size, the threads per inch, and how the pipe will be used. The first number (3/4) refers to the pipe’s nominal size or outside diameter. The second number (14) will give the threads per inch. The string of letters will describe the threading standard (N stands for National), the type of material being threaded (P stands for Pipe), the thread type (T stands for tapered), and the pipe’s intended use (G stands for gas). All pipe nomenclature must have four letters. Without the fourth letter the use of the pipe and the proper threading procedure cannot be determined.

A – Aeronautical

C – Coupling

F – Fuel

G – Gas

H – Hose

I – Intermediate

L – Loose

N – National

P – Pipe

R – Railing

S – Straight

T – Tapered

Steel Dragon Tools manufactures a variety of different pipe dies and die heads for use on the pipe material listed above. For more information on Steel Dragon Tools pipe threading machines, pipe dies, or die heads please click here or contact customer service here or by phone at 734-224-7112.

Steel Dragon Tools pipe dies are available for purchase from AffordableTool.com and ToolzUnlimited.com.

Pipe Threading Tips

When threading pipe with a Steel Dragon Tools die head, or any die head for that matter, it is important to remember that the scale on the top of the die head i s for reference only. The scale is used to get as close as possible to the correct threading size but it is up to the operator to test the die head, dies, and pipe.

s for reference only. The scale is used to get as close as possible to the correct threading size but it is up to the operator to test the die head, dies, and pipe.

Start by setting the die head to the desired threading capacity. Thread a sample piece of pipe and test the pipe with a c orresponding fitting. A properly threaded piece of pipe will make one and a half to two full turns within the fitting before meeting resistance. A pipe that does not make one and a half to two full turns has threads that were cut too shallow. Shallow threads will not allow the pipe and the fitting to seal properly. A pipe that turns more than two full rotations in the fitting has threads that were cut too deep. A pipe with threads that are too deep may bottom out in the fitting, preventing the pipe and fitting from being tightened.

orresponding fitting. A properly threaded piece of pipe will make one and a half to two full turns within the fitting before meeting resistance. A pipe that does not make one and a half to two full turns has threads that were cut too shallow. Shallow threads will not allow the pipe and the fitting to seal properly. A pipe that turns more than two full rotations in the fitting has threads that were cut too deep. A pipe with threads that are too deep may bottom out in the fitting, preventing the pipe and fitting from being tightened.

Pipe threading is not an exact science, it will take a little finesse and patience to successfully thread pipe and it is a good idea to test the threaded pipe on a regular basis. It is also important to remember that in most cases a sealant will be used on the pipe and fitting to prevent leaks. Using a sealant will allow the operator a bit of leeway when threading pipe.

The pipes themselves can also cause problems during threading. Pipes may not be true to their stated measurements. For example, a 1-inch pipe may be slightly smaller at 15/16 inches in diameter or slightly larger at 1-1/16 inches in diameter. The pipe may also be metric. A 25-millimeter pipe is slightly smaller than a 1-inch pipe but can look identical to the naked eye. Pipe variance must also be considered. Defects in the pipe from the manufacturing process can result in the pipe not being uniform from one end to the other. A pipe might measure 1 in. at the end, bow out to 1-1/16 in. at the middle before returning to 1 in. at the other end. It is always a good idea to periodically test the threaded pipe with a fitting to ensure a tight seal.

More information on Steel Dragon Tools die heads and dies can be found by following the links or calling customer service at 734-224-7112.

Steel Dragon Tools die heads and dies are available for purchase from Craig’s Affordable Tools or Toolz Unlimited.

Best Practices to Ensure High-Quality Products

Steel Dragon Tools has built a reputation manufacturing quality tools and machines while pricing them to beat the competition. Setting forth and following best practices ensures that every product from Steel Dragon Tools meets or exceeds customer expectations and any applicable regulations. Steel Dragon Tools best practices include:

- All Steel Dragon Tools are CE Approved and government tested.

- An on-staff master technician inspects all Steel Dragon Tools to ensure top-of-the-line performance.

- Live, on-site customer service representatives provide valuable product knowledge. Customer service representatives are available to answer questions or offer technical

assistance on Steel Dragon Tools. Customer service representatives can be reached Monday through Friday, 8:00 a.m. to 6:00 p.m. EST at 734-224-7112. - All products manufactured by Steel Dragon Tools are backed by a one year warranty against manufacturer defects.

For more information on Steel Dragon Tools contact customer service here or by phone at 734-224-7112.

Steel Dragon Tools are available for purchase from AffordableTool.com and ToolzUnlimited.com.

Let Steel Dragon Tools Help!

Call Steel Dragon Tools toll free at 734-224-7112. Live customer service representatives are on hand from 8:00 a.m. to 6 p.m., EST. Monday through Friday. Steel Dragon Tools strives to provide, live, personalized customer service. Whether you have a simple question or need in depth technical assistance, do not hesitate to call.

Steel Dragon Tools can be reached by e-mail at customerservice@steeldragontools.com. Customers will receive a response to all e-mails within 24 hours. Customer Service representatives at Steel Dragon Tools will typically answer all e-mails within the day, if not the hour.