Obscure Fact About the 535

Steel Dragon Tools has over a decade of experience refurbishing pipe threading machines and accessories. The RIDGID® 535 is a prime candidate for reconditioning and can be found quite often in the Steel Dragon Tools shop. The 535 debuted on the market in 1957 and has been running in one form or another for over 50 years. Despite the years of experience, the technicians in the Steel Dragon Tools shop are always learning something new. In this case, the technicians pointed out that an 815A die head is not compatible on a 535 Version 1 machines that is equipped with a 340 Reamer.

This is a very specific issue that won’t affect most customers who use a 535 Version 1 machine. While the 815A die head is compatible with the 535, most customers will use the 811A die head. The 811A die head is much more common and is included with all reconditioned RIDGID® 535 packages offered by Steel Dragon Tools. For customers who have a 535 Version 1 machine and want to use an 815A die head, be sure to check which reamer in on the machine.

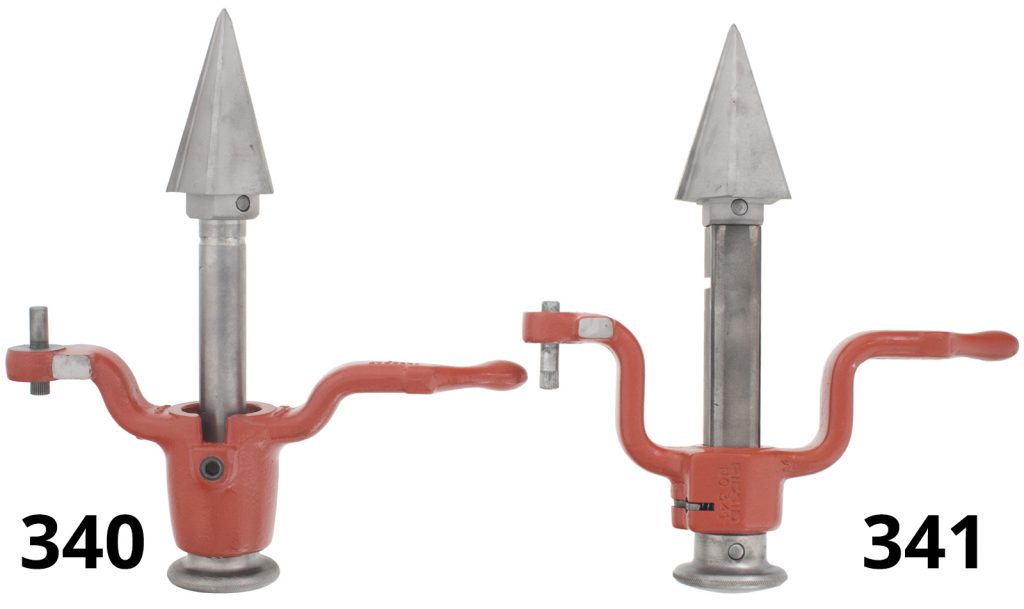

Over the years, as the 535 machine changed from Version 1 to Version 2 to Version 3, the attachments changed slightly as well. The 811 die head became the 811A die head and allowed for automatic oiling. The 815A die head was later introduced with an automatic opening feature that opens the die head when threading is complete. The 340 reamer was updated slightly to become the 341 reamer.

The 341 reamer is standard on later model 535 machines but will also fit the original 535 design. The difference between the 340 and 341 is nominal. The only thing that has changed over 50 years is the shape of the reamer arm. The 341 reamer has a shallow arm while the 340 reamer has a much more pronounced arm. It is the arm of the 340 reamer that will contact the 815A die head trigger, preventing the reamer from raising or lowering on the machine. This is only an issue when using an 815A die head on a RIDGID® 535 Version 1 machine that is equipped with a 340 reamer.

To learn more about Steel Dragon Tools reconditioned RIDGID® 535 machines, click here.

To learn about the difference between 811 and 815 die heads, click here.

For more information on Steel Dragon Tools call 734-224-7112 or e-mail customer service here.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon, Sears, and Walmart.

Steel Dragon Tools is always looking for used or broken pipe threading machines and pipe threading accessories. Click here for the purchase list and prices.

We are not an authorized distributor of RIDGID® and/or Ridge products. RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

“A” is for Automatic – 811A and 815A

Die heads for most Steel Dragon Tools and RIDGID® power pipe threading machines will either be automatic or non-automatic. Automatic refers the die head’s ability to automatically oil the pipe during the pipe threading process. These die heads will have a through-head oiling system. Automatic die heads will also have an “A” designation in their name like 811A or 815A.

The die head will connect to the pipe threading machine’s oil reservoir, if the machine has one (Steel Dragon Tools and RIDGID® 300 Power Drives do not have an oil reservoir and require a separate, manually operated oiler – like the Steel Dragon Tools 418 Oiler).

A pump in the pipe threading machine will push pipe threading oil to the die head where it will be distributed over the pipe during the pipe threading process. The automatic-style die head is now used across the industry. Non-automatic 811 and 815 die heads are typically not sold as new but can be found used or reconditioned. Steel Dragon Tools buys and reconditions used and broken pipe threading machines and accessories, including RIDGID® 811, 811A, 815, and 815A die heads.

Click here for more information on selling used equipment to Steel Dragon Tools.

Click here to learn more about the importance of pipe threading oil.

Click here to learn more about the difference between 811 and 815 die heads.

For more information on Steel Dragon Tools call 734-224-7112 or e-mail customerservice@steeldragontools.com.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon, Sears, and Walmart.

RIDGID® marks are trademarks of RIDGID, Inc and are used only for product identification purposes.

811 vs 815 Die Head Debate

A die head (or two) is a requirement for most industry-standard pipe threading machines. Using a Steel Dragon Tools 300, 300C, 7090-PRO, 7090i, 7090e, or a RIDGID® 300, 300A, 500A, 535, 535A, 800, 801, 802, or 1822 pipe threading machine will require a die head. Pipe threading professionals can choose between the 811- or the 815-style die head. (Most 811- and 815-style die heads are now being manufactured with automatic oiling operation, designated by the letter A — more on this next week.)

A die head (or two) is a requirement for most industry-standard pipe threading machines. Using a Steel Dragon Tools 300, 300C, 7090-PRO, 7090i, 7090e, or a RIDGID® 300, 300A, 500A, 535, 535A, 800, 801, 802, or 1822 pipe threading machine will require a die head. Pipe threading professionals can choose between the 811- or the 815-style die head. (Most 811- and 815-style die heads are now being manufactured with automatic oiling operation, designated by the letter A — more on this next week.)

The main difference between the 811 and the 815 comes in operation. The 815 die head has a trigger mechanism that will automatically open the die head and stop the threading process once a certain number of threads have been cut. The 811 die head has a quick open lever that must be opened manually to stop the pipe threading process. Both die heads can be used to thread pipe and bolts, both thread in the right-hand direction, and both have the same threading capacities.

Seems like an easy choice, right? However, the 811 die head allows for a flexibility in threading that the 815 cannot accommodate. The 815 die head will always cut the same number of threads per pipe size before the pipe hits the trigger and stops the threading process. The 811 die head can thread further down the pipe should the need arise.

The 811 die head will also be more reliable in the long run since there are no extra mechanical pieces to break or malfunction. Price-wise, the 815 will be slightly more expensive than the 811 but not by much.

Steel Dragon Tools manufactures an 811A and 815A die head that will fit most industry standard pipe threading machines including Steel Dragon Tools and RIDGID® machines. Steel Dragon Tools 811A and 815A die heads are offered with an automatic oiling feature for use on pipe threading machines that have a pipe threading oil reservoir.

For more information on Steel Dragon Tools call 734-224-7112 or e-mail customerservice@steeldragontools.com.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon, Sears, and Walmart.

Steel Dragon Tools is always looking for used or broken pipe threading machines and pipe threading accessories. Click here for the purchase list and prices.

We are not an authorized distributor of RIDGID® and/or Ridge products. RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

Making Pipe Dies Last

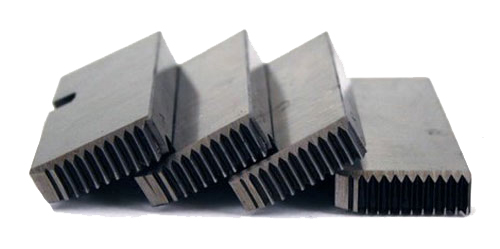

Quality pipe threading dies should last a very long time if care is taken to keep them in good working order. Steel Dragon Tools manufacturers dies that are compatible with several brand-name die heads and pipe threading machines. Steel Dragon Tools dies are made from a composite alloy or high-speed steel and, under proper working conditions, should last a very long time.

Quality pipe threading dies should last a very long time if care is taken to keep them in good working order. Steel Dragon Tools manufacturers dies that are compatible with several brand-name die heads and pipe threading machines. Steel Dragon Tools dies are made from a composite alloy or high-speed steel and, under proper working conditions, should last a very long time.

To get the most out of a set of Steel Dragon Tools dies, here are some important tips to keep in mind when threading pipe. The following tips should be applied to powered and manual pipe threading machines.

- Always use a high-quality pipe threading oil. High-quality pipe threading oil will reduce the friction between the dies and the pipe. The oil will also absorb heat during the threading process. Excess heat during the threading process can damage the dies and the pipe. Excess heat can cause metal chips to become welded to the dies. Metal chips in the die teeth will affect the consistency and shape of the threads.

- Keep the dies clean. Clean dies make for clean threads. After threading pipe, use a stiff-bristle wire brush to clean any debris that may be stuck in the die teeth.

- Install the dies properly into the die head. Dies that are not properly installed can result in damage to both the die teeth and the pipe. Double check to make sure the dies are properly installed before threading pipe.

Following these steps will help ensure that the Steel Dragon Tools dies enjoy a long operating life and provide you with many perfectly threaded pipes.

To view Steel Dragon Tools dies, click here.

For more information on the Steel Dragon Tools dies call 734-224-7112 or e-mail customerservice@steeldragontools.com.

Learn more about the importance of pipe threading oil.

Learn more about installing dies into die heads.

Learn more about Steel Dragon Tools die heads.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon and Walmart.

Sell Your Used Pipe Threading Tools

Steel Dragon Tools will buy used and broken pipe threading machines and accessories. Steel Dragon Tools started refurbishing pipe threading machines in 2009 and is always looking for items to refurbish.

Power Pipe Threaders:

| RIDGID® | 1822 Pipe Threader |

| RIDGID® | 1224 Pipe Threader with Die Head |

| RIDGID® | 1215 Pipe Threader |

| RIDGID® | 700 Handheld Threader |

| RIDGID® | All Model 535 Pipe Threaders |

| RIDGID® | 300C Pipe Threader |

| RIDGID® | 300 Power Drive and Accessories |

Carts for Machines:

| RIDGID® | 150A Cart |

| RIDGID® | 200A Cart |

Power Threader Parts:

| RIDGID® | Cast and Stamped Foot Pedals |

| RIDGID® | 300 Motors and Gearboxes |

| RIDGID® | 300C Motors and Gearboxes |

| RIDGID® | 535 Motors and Gearboxes |

Pipe Threading Accessories:

| RIDGID® | 141 Hog Heads |

| RIDGID® | 161 Hog Heads |

| RIDGID® | 811 and 815 Die Heads |

| RIDGID® | 811A and 815A Die Heads |

| RIDGID® | 12R Die Heads |

| RIDGID® | 12R Ratchet |

| RIDGID® | 774 Square Drive Adpt. |

| RIDGID® | 844 Drive Bars |

| RIDGID® | 840A Universal Driveshafts |

| RIDGID® | 2A Pipe Cutters |

| RIDGID® | 728 Loops for Hog Head |

| RIDGID® | 775 Support Arm |

| RIDGID® | 1452 Tric Trays |

| RIDGID® | 311 Carriages |

| RIDGID® | 341 Reamers |

| RIDGID® | 360 Cutters |

| RIDGID® | 254 Spiral Reamers |

Tristands and Vises:

| RIDGID® | 1205 Tristand |

| RIDGID® | 460 Chain Vise Tristand |

| RIDGID® | 450 Chain Vise Tristand |

| RIDGID® | 40-A Yoke Vise Tristand |

All prices will vary depending on machine condition and current inventory.

Please send photos and contact information to: apietszak@steeldragontools.com or call 734-224-7112.

We are not an authorized distributor of RIDGID® and/or Ridge products. RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

Dies from Steel Dragon Tools

Steel Dragon Tools manufactures high speed steel and alloy dies to meet or exceed industry specifications. These dies are compatible with Steel Dragon Tools pipe threading machines and can be used in compatible dies heads with other machine brands.

Dies are an essential part of the pipe threading process. Sharp, well-made dies will ensure consistent, useable threads. Dies with dull or chipped teeth will result in poorly threaded pipe that will not seal properly. Replacing dies as they wear or chip is a necessity but it doesn’t have to break the bank.

Steel Dragon Tools dies are compatible with the specified Steel Dragon Tools pipe threaders and will fit certain other brands. Steel Dragon Tools dies will match the quality of comparable dies but for a fraction of the price. Steel Dragon Tools can offer dies for far less since there is no middle man. Steel Dragon Tools manufacturers the dies and then sells them directly to the customer. Buy an extra set of dies and never worry about chipping a tooth while on the job site.

Steel Dragon Tools manufactures dies for powered and manual pipe threading machines. Many of these dies can be used in compatible die heads from Wheeler Rex® and RIDGID® machines.

For more information on the Steel Dragon Tools dies, click here. For more information on Steel Dragon Tools pipe threading machines, click here.

For more information about Steel Dragon Tools please call contact Customer Service at 734-224-7112 or by e-mail here.

The full line of Steel Dragon Tools are available for purchase from Craig’s Affordable Tools or Toolz Unlimited.

We are not an authorized distributor of RIDGID® and/or Ridge products. RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

Steel Dragon Tools Buys Used Equipment

Steel Dragon Tools will buy used and broken pipe threading machines and accessories. Steel Dragon Tools has ten years of experience refurbishing pipe threading machines and is always looking for items to refurbish.

Steel Dragon Tools will buy the following machines:

| MANUFACTURER | MODEL | |

|---|---|---|

| RIDGID® | 300 Power Drive | |

| RIDGID® | 300 Power Drive with Stand | |

| RIDGID® | 300 Power Drive with Stand, Carriage, Die Head, Cutter, Reamer | |

| RIDGID® | 811A and 815A Universal Die Heads | |

| RIDGID® | 811 and 815 Universal Die Heads (older models) | |

| RIDGID® | 141 with dies in good condition | |

| RIDGID® | 161 with dies in good condition | |

| RIDGID® | 1224 Pipe Threader | |

| RIDGID® | 535 Pipe Threader (Old Style) with die head | |

| RIDGID® | 535 Pipe Threader (New Style) with die head | |

| RIDGID® | 535M Pipe Threader | |

| RIDGID® | 1822 Pipe Threader | |

| RIDGID® | 300C Pipe Threader | |

| RIDGID® | 700 Power Drive | |

| RIDGID® | 12R Die Heads | |

| RIDGID® | 42620 Model 774 Square Drive Adapter | |

| RIDGID® | 42405 844 Drive Bar for 141/161 geared pipe threaders | |

| RIDGID® | 19366 758 Loop for 141/161 geared pipe threaders | |

| RIDGID® | 40A TRISTAND® | |

| RIDGID® | 460 TRISTAND® |

All prices will vary depending on machine condition and current inventory.

Reduced prices will be offered for machines with cracked or missing feet, missing front chuck, etc.

Please send photos and contact information to: apietszak@steeldragontools.com or call 734-224-7112.

RIDGID® marks are trademarks of RIDGID, Inc and are used only for product identification purposes.

Pipe Threading Tips

When threading pipe with a Steel Dragon Tools die head, or any die head for that matter, it is important to remember that the scale on the top of the die head i s for reference only. The scale is used to get as close as possible to the correct threading size but it is up to the operator to test the die head, dies, and pipe.

s for reference only. The scale is used to get as close as possible to the correct threading size but it is up to the operator to test the die head, dies, and pipe.

Start by setting the die head to the desired threading capacity. Thread a sample piece of pipe and test the pipe with a c orresponding fitting. A properly threaded piece of pipe will make one and a half to two full turns within the fitting before meeting resistance. A pipe that does not make one and a half to two full turns has threads that were cut too shallow. Shallow threads will not allow the pipe and the fitting to seal properly. A pipe that turns more than two full rotations in the fitting has threads that were cut too deep. A pipe with threads that are too deep may bottom out in the fitting, preventing the pipe and fitting from being tightened.

orresponding fitting. A properly threaded piece of pipe will make one and a half to two full turns within the fitting before meeting resistance. A pipe that does not make one and a half to two full turns has threads that were cut too shallow. Shallow threads will not allow the pipe and the fitting to seal properly. A pipe that turns more than two full rotations in the fitting has threads that were cut too deep. A pipe with threads that are too deep may bottom out in the fitting, preventing the pipe and fitting from being tightened.

Pipe threading is not an exact science, it will take a little finesse and patience to successfully thread pipe and it is a good idea to test the threaded pipe on a regular basis. It is also important to remember that in most cases a sealant will be used on the pipe and fitting to prevent leaks. Using a sealant will allow the operator a bit of leeway when threading pipe.

The pipes themselves can also cause problems during threading. Pipes may not be true to their stated measurements. For example, a 1-inch pipe may be slightly smaller at 15/16 inches in diameter or slightly larger at 1-1/16 inches in diameter. The pipe may also be metric. A 25-millimeter pipe is slightly smaller than a 1-inch pipe but can look identical to the naked eye. Pipe variance must also be considered. Defects in the pipe from the manufacturing process can result in the pipe not being uniform from one end to the other. A pipe might measure 1 in. at the end, bow out to 1-1/16 in. at the middle before returning to 1 in. at the other end. It is always a good idea to periodically test the threaded pipe with a fitting to ensure a tight seal.

More information on Steel Dragon Tools die heads and dies can be found by following the links or calling customer service at 734-224-7112.

Steel Dragon Tools die heads and dies are available for purchase from Craig’s Affordable Tools or Toolz Unlimited.