Making Pipe Dies Last

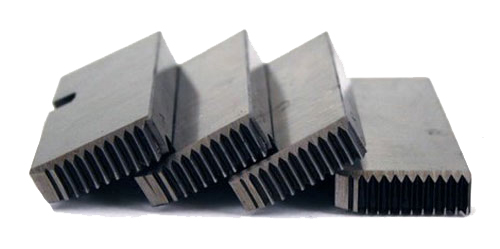

Quality pipe threading dies should last a very long time if care is taken to keep them in good working order. Steel Dragon Tools manufacturers dies that are compatible with several brand-name die heads and pipe threading machines. Steel Dragon Tools dies are made from a composite alloy or high-speed steel and, under proper working conditions, should last a very long time.

Quality pipe threading dies should last a very long time if care is taken to keep them in good working order. Steel Dragon Tools manufacturers dies that are compatible with several brand-name die heads and pipe threading machines. Steel Dragon Tools dies are made from a composite alloy or high-speed steel and, under proper working conditions, should last a very long time.

To get the most out of a set of Steel Dragon Tools dies, here are some important tips to keep in mind when threading pipe. The following tips should be applied to powered and manual pipe threading machines.

- Always use a high-quality pipe threading oil. High-quality pipe threading oil will reduce the friction between the dies and the pipe. The oil will also absorb heat during the threading process. Excess heat during the threading process can damage the dies and the pipe. Excess heat can cause metal chips to become welded to the dies. Metal chips in the die teeth will affect the consistency and shape of the threads.

- Keep the dies clean. Clean dies make for clean threads. After threading pipe, use a stiff-bristle wire brush to clean any debris that may be stuck in the die teeth.

- Install the dies properly into the die head. Dies that are not properly installed can result in damage to both the die teeth and the pipe. Double check to make sure the dies are properly installed before threading pipe.

Following these steps will help ensure that the Steel Dragon Tools dies enjoy a long operating life and provide you with many perfectly threaded pipes.

To view Steel Dragon Tools dies, click here.

For more information on the Steel Dragon Tools dies call 734-224-7112 or e-mail customerservice@steeldragontools.com.

Learn more about the importance of pipe threading oil.

Learn more about installing dies into die heads.

Learn more about Steel Dragon Tools die heads.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon and Walmart.

Tips and Tricks for the 535

One of the common complaints from users of the Steel Dragon Tools Reconditioned RIDGID® 535 is that the chuck or the pipe wobbles, resulting in unusable threads.

If the machine is not threading properly, check the dies first. A good set of dies should last a very long time. Unless the die teeth are chipped or otherwise damaged, the dies should work without issue. Next, check the installation. Dies will fit into the die head only one way but should be installed securely and in the proper order. If the dies are installed properly, check the rear centering chuck. The rear centering chuck simply keeps the pipe centered in the machine. Do not over tighten the rear chuck. Only hand tighten the rear chuck, do not use tools.

The front chuck does most of the work when threading pipe. The front chuck should only be hand tightened. Do not use tools to tighten the front chucks.

To tighten front and rear chuck, spin chuck forcefully in a counter clockwise motion. The chuck will tighten around the pipe. Do this several times to ensure a snug fit. The sound the that the chuck makes will change as it tightens. Once the sound changes, the chuck is tight. A tightened chuck will give off a short, dull sound as the chuck has already tightened around the pipe.

Other Tips to Remember:

The guide marks on the die head are not exact. Always run a simple threading test before threading the actual work piece. Use a properly-sized fitting to test the threads. A properly threaded pipe will allow the fitting to turn one and a half to two turns before meeting any resistance. If the fitting continues to turn easily or does not turn at all, the die head settings will need to be adjusted.

Threads should only be cut to the width of the die head. Cutting threads too far down the pipe may result in unusable threads. Some dies are designed to cut tapered threads. Cutting beyond the width of the die head will result in straight threads instead of the desired tapered threads.

For more information about Steel Dragon Tools please call contact Customer Service at 734-224-7112 or by e-mail here.

RIDGID® marks are trademarks of RIDGID, Inc and are used only for product identification purposes.

Steel Dragon Tools 819 Nipple Chuck

The Steel Dragon Tools 819 is a nipple chuck adapter used to create pipe nipples on 1/2-inch to 2-inch pipe. The Steel Dragon Tools 819 can be used with both RIDGID® and Steel Dragon Tools pipe threading machines, including model numbers 300, both power drive and compact, as well as 535, 1882, and 1224.

The Steel Dragon Tools 819 is a nipple chuck adapter used to create pipe nipples on 1/2-inch to 2-inch pipe. The Steel Dragon Tools 819 can be used with both RIDGID® and Steel Dragon Tools pipe threading machines, including model numbers 300, both power drive and compact, as well as 535, 1882, and 1224.

The Steel Dragon Tools 819 package includes a nipple chuck wrench, adapter hanger for storage, standard insert and five adapters: 1/2 in., 3/4 in., 1 in., 1-1/4 in., and 1-1/2 in. The base itself serves as the 2-inch adapter.

To create a pipe nipple, install pipe into the threading machine and thread pipe as normal. Cut the pipe to the desired length. Install the Steel Dragon Tools 819 nipple adapter into the pipe threading machine and screw the threaded end of pipe into the adapter. Do not over-tighten the pipe into the nipple adapter. Hand tight will be sufficient. Once the pipe is secure in the adapter, thread it as normal.

It is important to make sure the initial thread is the correct dimensions. If the threads are over-sized or under-sized, the pipe may become lodged in the adapter. Removing a lodged pipe will require a pipe wrench and considerable force. Test the threads with a thread gauge or corresponding fitting to ensure the threads are dimensionally correct. A fitting should turn 1-1/2 to 2 turns on a properly threaded pipe.

Insert the plug end of the nipple chuck wrench into the holes in the adapter to release the tension spring inside the adapter. Unscrew the pipe from the adapter while relieving the tension. A pipe wrench may be required to unscrew the pipe from the adapter. The pipe can become lodged in the adapter if the threads are not dimensionally correct. The pipe will tighten by itself in the adapter during the threading process.

For more information about Steel Dragon Tools please call contact Customer Service at 734-224-7112 or by e-mail here.

The full line of Steel Dragon Tools are available for purchase from Craig’s Affordable Tools or Toolz Unlimited.

RIDGID® marks are trademarks of RIDGID, Inc and are used only for product identification purposes.

Reconditioning Pipe Threaders – The Process Part 3

Steel Dragon Tools has over a decade worth of experience refurbishing used pipe threading machines. Steel Dragon Tools will buy used RIDGID® pipe threading machines in almost any condition. These machines are processed, repaired, and sent back to the market good as new. Refurbished pipe threading machines from Steel Dragon Tools are guaranteed to work like new and cost far less than a brand-new pipe threading machine. This post is the second part of a three-part series. Click here for part one. Click here for part two.

The final part of the process is sending the finished machines out to the customer. After the used or broken pipe threading machines have been repaired and tested they are boxed and ready to ship. Refurbished pipe threading machines from Steel Dragon Tools are guaranteed to operate like new and are available for a fraction of the cost of a new machine. Reconditioned RIDGID® pipe threading machines by Steel Dragon Tools are available for purchase online from our distribution partners Craig’s Affordable Tool and Toolz Unlimited. Customers can also purchase these machines online from Amazon, eBay, and Sears.

Reconditioned RIDGID® pipe threading machines by Steel Dragon Tools are sold with a variety of accessories including reconditioned RIDGID® die heads and dies or Steel Dragon Tools die heads and dies. Steel Dragon Tools manufactures a full line of die heads and dies that are compatible with many of the industry-standard machines.

For more information about Steel Dragon Tools please call contact Customer Service at 734-224-7112 or by e-mail here.

RIDGID® marks are trademarks of RIDGID, Inc and are used only for product identification purposes.

Reconditioning Pipe Threaders – The Process Part 2

Steel Dragon Tools has over a decade worth of experience refurbishing used pipe threading machines. Steel Dragon Tools will buy used RIDGID® pipe threading machines in almost any condition. These machines are processed, repaired, and sent back to the market good as new. Refurbished pipe threading machines from Steel Dragon Tools are guaranteed to work like new and cost far less than a brand-new pipe threading machine.

This post is the second part of a three-part series. Click here for part one.

The second part of the process starts with a thorough cleaning. All parts of the machine are degreased and then inspected to check for integrity. The parts are then sent to be sandblasted. Sand blasting removes old paint and rust in preparation for paint. After sand blasting, the pieces are sent to the paint room. All parts are repainted to match the original machine using a durable, high-quality, rust-resistant enamel.

Once the paint has dried, the machine is ready to be reassembled. New parts, including motor field, brushes, and armatures, as well as gears, bearings, and power cord are installed in the machine.

After the machine has been reassembled it is tested by a technician to ensure the machine will operate in like-new condition. Once the testing has been completed, the machine is boxed and ready to ship.

Steel Dragon Tools offers different packages with all the refurbished pipe threading machines. These packages include extra dies or die heads, high-quality pipe threading oil, pipe stands, and other accessories. Steel Dragon Tools also offers packages with new die heads and dies manufactured by Steel Dragon Tools.

For more information about Steel Dragon Tools please call contact Customer Service at 734-224-7112 or by e-mail here.

RIDGID® marks are trademarks of RIDGID, Inc and are used only for product identification purposes.

Reconditioning Pipe Threaders – The Process Part 1

The process starts when Steel Dragon Tools buys a used pipe threading machine. Steel Dragon Tools will buy a variety of models as well as the accessories. For more information on selling a used pipe threading machine, please click here.

Steel Dragon Tools actively seeks out used or broken machines for repair. Shop manager David Krell searches Craigslist, eBay, and other internet forums and classifieds to find these used machines. Steel Dragon Tools can arrange for shipping. After working out a deal with the seller, these machines are brought into the shop to be refurbished.

The used machines are brought into the shop and disassembled. All pieces are examined to determine condition. Parts in poor condition will be replaced to ensure safety and effective operation. All wear items, including motor field, brushes, and armatures, as well as gears, bearings, and power cord will be inspected and replaced as needed.

Steel Dragon Tools also offers repair service for many of the most popular pipe threading machines on the market. Along with repair shop, Steel Dragon Tools also manufactures a wide variety of industrial tools including a full line of pipe threading machines die heads, dies, and replacement parts that will fit many of the industry-standard machines. Steel Dragon Tools also manufactures cable wire hoists, core drill rigs, drain cleaning machines, lifting magnets, annular cutters, and pipe inspection cameras. To view a full list of Steel Dragon Tools products, please click here.

For more information about Steel Dragon Tools please call contact Customer Service at 734-224-7112 or by e-mail here.

Steel Dragon Tools is not an authorized distributor of RIDGID® and/or Ridge products. RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

Sell Your Used Pipe Threading Tools

Steel Dragon Tools will buy used and broken pipe threading machines and accessories. Steel Dragon Tools started refurbishing pipe threading machines in 2009 and is always looking for items to refurbish.

Power Pipe Threaders:

| RIDGID® | 1822 Pipe Threader |

| RIDGID® | 1224 Pipe Threader with Die Head |

| RIDGID® | 1215 Pipe Threader |

| RIDGID® | 700 Handheld Threader |

| RIDGID® | All Model 535 Pipe Threaders |

| RIDGID® | 300C Pipe Threader |

| RIDGID® | 300 Power Drive and Accessories |

Carts for Machines:

| RIDGID® | 150A Cart |

| RIDGID® | 200A Cart |

Power Threader Parts:

| RIDGID® | Cast and Stamped Foot Pedals |

| RIDGID® | 300 Motors and Gearboxes |

| RIDGID® | 300C Motors and Gearboxes |

| RIDGID® | 535 Motors and Gearboxes |

Pipe Threading Accessories:

| RIDGID® | 141 Hog Heads |

| RIDGID® | 161 Hog Heads |

| RIDGID® | 811 and 815 Die Heads |

| RIDGID® | 811A and 815A Die Heads |

| RIDGID® | 12R Die Heads |

| RIDGID® | 12R Ratchet |

| RIDGID® | 774 Square Drive Adpt. |

| RIDGID® | 844 Drive Bars |

| RIDGID® | 840A Universal Driveshafts |

| RIDGID® | 2A Pipe Cutters |

| RIDGID® | 728 Loops for Hog Head |

| RIDGID® | 775 Support Arm |

| RIDGID® | 1452 Tric Trays |

| RIDGID® | 311 Carriages |

| RIDGID® | 341 Reamers |

| RIDGID® | 360 Cutters |

| RIDGID® | 254 Spiral Reamers |

Tristands and Vises:

| RIDGID® | 1205 Tristand |

| RIDGID® | 460 Chain Vise Tristand |

| RIDGID® | 450 Chain Vise Tristand |

| RIDGID® | 40-A Yoke Vise Tristand |

All prices will vary depending on machine condition and current inventory.

Please send photos and contact information to: apietszak@steeldragontools.com or call 734-224-7112.

We are not an authorized distributor of RIDGID® and/or Ridge products. RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

The Art of Active Listening

By Samantha Benson, Customer Service Manager at Steel Dragon Tools

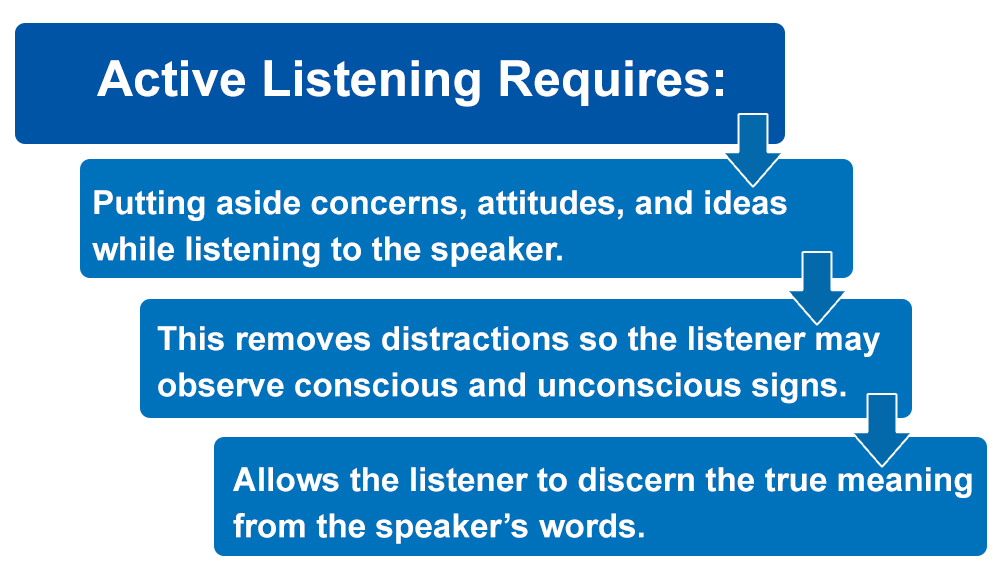

The customer service representative at Steel Dragon Tools have all been trained to be active listeners. Active listening is a way of communicating with another person to improve mutual understanding. Sometimes, when two people are talking to each other, one or both may not be actively listening, they may be distracted or simply waiting for the other person to finish so they can speak.

Below are some active listening techniques that we use to help our customer service representative become better communicators. These techniques work well in the realm of customer service but can be applied in any situation to help us understand each other better and improve our daily relationships.

Active Listening in Every Situation

Do:

- Paraphrase the speaker’s words.

- Be mentally prepared to listen.

- Evaluate the speech, not the speaker.

- Be unbiased toward the speaker by depersonalizing and stepping away from emotional response.

- Fight distractions by tuning out external sounds.

- Ask questions to clarify and corroborate thoughts.

Don’t:

- Show boredom.

- Get distracted by outside stimuli.

- Prepare your response or mentally argue while the speaker is talking.

- Interrupt the speaker.

- Reflex on the rightness or wrongness of what is being said.

This is the second part of the article Communicating for Success. To view the first part of the article, click here.

Steel Dragon Tools customer service can be contacted by e-mail or by phone at 734-224-7112.

Dies from Steel Dragon Tools

Steel Dragon Tools manufactures high speed steel and alloy dies to meet or exceed industry specifications. These dies are compatible with Steel Dragon Tools pipe threading machines and can be used in compatible dies heads with other machine brands.

Dies are an essential part of the pipe threading process. Sharp, well-made dies will ensure consistent, useable threads. Dies with dull or chipped teeth will result in poorly threaded pipe that will not seal properly. Replacing dies as they wear or chip is a necessity but it doesn’t have to break the bank.

Steel Dragon Tools dies are compatible with the specified Steel Dragon Tools pipe threaders and will fit certain other brands. Steel Dragon Tools dies will match the quality of comparable dies but for a fraction of the price. Steel Dragon Tools can offer dies for far less since there is no middle man. Steel Dragon Tools manufacturers the dies and then sells them directly to the customer. Buy an extra set of dies and never worry about chipping a tooth while on the job site.

Steel Dragon Tools manufactures dies for powered and manual pipe threading machines. Many of these dies can be used in compatible die heads from Wheeler Rex® and RIDGID® machines.

For more information on the Steel Dragon Tools dies, click here. For more information on Steel Dragon Tools pipe threading machines, click here.

For more information about Steel Dragon Tools please call contact Customer Service at 734-224-7112 or by e-mail here.

The full line of Steel Dragon Tools are available for purchase from Craig’s Affordable Tools or Toolz Unlimited.

We are not an authorized distributor of RIDGID® and/or Ridge products. RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

Steel Dragon Tools Buys Used Equipment

Steel Dragon Tools will buy used and broken pipe threading machines and accessories. Steel Dragon Tools has ten years of experience refurbishing pipe threading machines and is always looking for items to refurbish.

Steel Dragon Tools will buy the following machines:

| MANUFACTURER | MODEL | |

|---|---|---|

| RIDGID® | 300 Power Drive | |

| RIDGID® | 300 Power Drive with Stand | |

| RIDGID® | 300 Power Drive with Stand, Carriage, Die Head, Cutter, Reamer | |

| RIDGID® | 811A and 815A Universal Die Heads | |

| RIDGID® | 811 and 815 Universal Die Heads (older models) | |

| RIDGID® | 141 with dies in good condition | |

| RIDGID® | 161 with dies in good condition | |

| RIDGID® | 1224 Pipe Threader | |

| RIDGID® | 535 Pipe Threader (Old Style) with die head | |

| RIDGID® | 535 Pipe Threader (New Style) with die head | |

| RIDGID® | 535M Pipe Threader | |

| RIDGID® | 1822 Pipe Threader | |

| RIDGID® | 300C Pipe Threader | |

| RIDGID® | 700 Power Drive | |

| RIDGID® | 12R Die Heads | |

| RIDGID® | 42620 Model 774 Square Drive Adapter | |

| RIDGID® | 42405 844 Drive Bar for 141/161 geared pipe threaders | |

| RIDGID® | 19366 758 Loop for 141/161 geared pipe threaders | |

| RIDGID® | 40A TRISTAND® | |

| RIDGID® | 460 TRISTAND® |

All prices will vary depending on machine condition and current inventory.

Reduced prices will be offered for machines with cracked or missing feet, missing front chuck, etc.

Please send photos and contact information to: apietszak@steeldragontools.com or call 734-224-7112.

RIDGID® marks are trademarks of RIDGID, Inc and are used only for product identification purposes.