“A” is for Automatic – 811A and 815A

Die heads for most Steel Dragon Tools and RIDGID® power pipe threading machines will either be automatic or non-automatic. Automatic refers the die head’s ability to automatically oil the pipe during the pipe threading process. These die heads will have a through-head oiling system. Automatic die heads will also have an “A” designation in their name like 811A or 815A.

The die head will connect to the pipe threading machine’s oil reservoir, if the machine has one (Steel Dragon Tools and RIDGID® 300 Power Drives do not have an oil reservoir and require a separate, manually operated oiler – like the Steel Dragon Tools 418 Oiler).

A pump in the pipe threading machine will push pipe threading oil to the die head where it will be distributed over the pipe during the pipe threading process. The automatic-style die head is now used across the industry. Non-automatic 811 and 815 die heads are typically not sold as new but can be found used or reconditioned. Steel Dragon Tools buys and reconditions used and broken pipe threading machines and accessories, including RIDGID® 811, 811A, 815, and 815A die heads.

Click here for more information on selling used equipment to Steel Dragon Tools.

Click here to learn more about the importance of pipe threading oil.

Click here to learn more about the difference between 811 and 815 die heads.

For more information on Steel Dragon Tools call 734-224-7112 or e-mail customerservice@steeldragontools.com.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon, Sears, and Walmart.

RIDGID® marks are trademarks of RIDGID, Inc and are used only for product identification purposes.

Making Pipe Dies Last

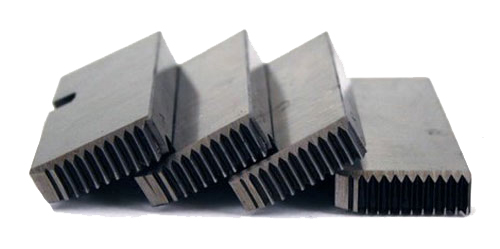

Quality pipe threading dies should last a very long time if care is taken to keep them in good working order. Steel Dragon Tools manufacturers dies that are compatible with several brand-name die heads and pipe threading machines. Steel Dragon Tools dies are made from a composite alloy or high-speed steel and, under proper working conditions, should last a very long time.

Quality pipe threading dies should last a very long time if care is taken to keep them in good working order. Steel Dragon Tools manufacturers dies that are compatible with several brand-name die heads and pipe threading machines. Steel Dragon Tools dies are made from a composite alloy or high-speed steel and, under proper working conditions, should last a very long time.

To get the most out of a set of Steel Dragon Tools dies, here are some important tips to keep in mind when threading pipe. The following tips should be applied to powered and manual pipe threading machines.

- Always use a high-quality pipe threading oil. High-quality pipe threading oil will reduce the friction between the dies and the pipe. The oil will also absorb heat during the threading process. Excess heat during the threading process can damage the dies and the pipe. Excess heat can cause metal chips to become welded to the dies. Metal chips in the die teeth will affect the consistency and shape of the threads.

- Keep the dies clean. Clean dies make for clean threads. After threading pipe, use a stiff-bristle wire brush to clean any debris that may be stuck in the die teeth.

- Install the dies properly into the die head. Dies that are not properly installed can result in damage to both the die teeth and the pipe. Double check to make sure the dies are properly installed before threading pipe.

Following these steps will help ensure that the Steel Dragon Tools dies enjoy a long operating life and provide you with many perfectly threaded pipes.

To view Steel Dragon Tools dies, click here.

For more information on the Steel Dragon Tools dies call 734-224-7112 or e-mail customerservice@steeldragontools.com.

Learn more about the importance of pipe threading oil.

Learn more about installing dies into die heads.

Learn more about Steel Dragon Tools die heads.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon and Walmart.

Steel Dragon Tools Buys Used Pipe Threading Equipment

Steel Dragon Tools buys used RIDGID® pipe threading equipment ranging from handheld pipe threader die heads, like the 12-R, up to heavy-duty models like the 1224 and 161. Steel Dragon Tools will also buy the various RIDGID® stands, die heads, and associated products.

Used RIDGID® models that Steel Dragon Tools will purchase:

- Machines: 700, 1215, 300, 300C, 1822, 535 (manual or automatic, all three generations), 1224

- Hog Heads: 141, 161

- Stands: 1206 (300 stand), 450, 460, 460-6(chain vises), 40A (yoke vise)

- Die Heads: 12-R, 811, 811a, 815, 815A, 711, 714

Steel Dragon Tools will also buy accessories that work with the units like drive adapters, pipe cutters, and pipe reamers. Steel Dragon Tools will consider items that are missing components or have been disassembled for purchase as parts units.

Selling used equipment is a great way to clean up the shop and make extra money at the same time. For more information about selling used equipment, please contact us by phone at 734-224-7112 or by e-mail here.

The Common Traits of High-Performance Threading Oil

One of the most important elements when threading pipe, manually or with a machine, is the use of high-performance threading oil. High-performance threading oil is critical to producing straight and sharp threads when threading pipe. High-quality, professional-grade pipe threading oil from Steel Dragon Tools will facilitate perfect pipe threads every time.

Not all pipe threading oil is created equal. High-performance threading oil has four common characteristics:

1. LUBRICITY. The oil must have high lubricity to minimize load and reduce friction. Threading oil with high lubricity will reduce the friction between the dies and the material being threaded. Threading oil chemically bonds to the threaded surface and transforms into a metal film as dies cut away material. This metal film lowers the coefficient of friction and the load is reduced, resulting in threads that are straight and sharp.

2. HEAT ABSORBPSTION. Threading oil must absorb heat and immediately conduct it away from the threads. Excessive heat at the cutting surface leads to premature wear of the dies, metal chips welded on to the cutting edge of the dies, and torn, disfigured, or wavy threads.

3. ADHESION. Threading oil should cling to the pipe surface even in extreme temperatures. Oil with the proper viscosity will stick to the surface of the pipe during the threading process. This oil will transform into a metal film, reducing friction and absorbing heat as the pipe is threaded. The lowered friction and cooler temperature will result in straight and sharp threads.

4. CONSISTENCY. The viscosity and effectiveness of the oil must remain consistent throughout its operating life. High-quality threading oil will resist oxidation and will not have any volatile c ompounds that can evaporate. The performance of the oil should remain effective throughout its life cycle.

ompounds that can evaporate. The performance of the oil should remain effective throughout its life cycle.

With proper care, high-quality threading oil will never need to be changed. Threading oil only needs to be changed if the oil is contaminated with solvents, other oils, dirt, or grit. New oil should be added as needed to maintain the proper level in the oil sump of the pipe threading machine or the oiling bucket. Oil loss while threading pipe is common since  the oil will stick to the threaded material.

the oil will stick to the threaded material.

High-performance threading oil from Steel Dragon Tools has high lubricity, and will absorb and dissipate heat immediately. Steel Dragon Tool threading oil easily clings to threading surfaces, and maintains a consistent viscosity throughout its operating life. Steel Dragon Tools threading oil does not contain PCBs, heavy metals, chlorine, or other halogens.

To purchase the Steel Dragon Tools high-performance threading oil, visit Craig’s Affordable Tools or Toolz Unlimited.

For more information on the Steel Dragon Tools high-performance threading oil call 734-224-7112 or e-mail customerservice@steeldragontools.com.