Steel Dragon Tools Buys Used Equipment

Steel Dragon Tools will buy used and broken pipe threading machines and accessories. Steel Dragon Tools has ten years of experience refurbishing pipe threading machines and is always looking for items to refurbish.

Steel Dragon Tools will buy the following machines:

| MANUFACTURER | MODEL | |

|---|---|---|

| RIDGID® | 300 Power Drive | |

| RIDGID® | 300 Power Drive with Stand | |

| RIDGID® | 300 Power Drive with Stand, Carriage, Die Head, Cutter, Reamer | |

| RIDGID® | 811A and 815A Universal Die Heads | |

| RIDGID® | 811 and 815 Universal Die Heads (older models) | |

| RIDGID® | 141 with dies in good condition | |

| RIDGID® | 161 with dies in good condition | |

| RIDGID® | 1224 Pipe Threader | |

| RIDGID® | 535 Pipe Threader (Old Style) with die head | |

| RIDGID® | 535 Pipe Threader (New Style) with die head | |

| RIDGID® | 535M Pipe Threader | |

| RIDGID® | 1822 Pipe Threader | |

| RIDGID® | 300C Pipe Threader | |

| RIDGID® | 700 Power Drive | |

| RIDGID® | 12R Die Heads | |

| RIDGID® | 42620 Model 774 Square Drive Adapter | |

| RIDGID® | 42405 844 Drive Bar for 141/161 geared pipe threaders | |

| RIDGID® | 19366 758 Loop for 141/161 geared pipe threaders | |

| RIDGID® | 40A TRISTAND® | |

| RIDGID® | 460 TRISTAND® |

All prices will vary depending on machine condition and current inventory.

Reduced prices will be offered for machines with cracked or missing feet, missing front chuck, etc.

Please send photos and contact information to: apietszak@steeldragontools.com or call 734-224-7112.

RIDGID® marks are trademarks of RIDGID, Inc and are used only for product identification purposes.

Steel Dragon Tools Line of Die Heads

Steel Dragon Tools manufactures a wide-range of die heads that will fit a variety of industry-standard pipe threaders, as well as the Steel Dragon Tools line machines. Steel Dragon Tools die heads will fit popular RIDGID® pipe threading machines, including Model 300, 535, and 1224 machines.

Steel Dragon Tools also manufacturers die heads for RIDGID® 11R and 12R Pipe Threaders. 11R and 12R die heads can be used manually with a ratchet handle or in conjunction with a power drive like the RIDGID® 41935 Model 700.

Steel Dragon Tools also manufacturers die heads that will fit certain Wheeler-Rex® pipe threading machines. The Steel Dragon Tools 70131 die head will the Wheeler-Rex® 6790 Pipe Threading Machine. All Steel Dragon Tools die heads will also fit the related Steel Dragon Tools pipe threading machines.

The Steel Dragon Tools line of die heads includes:

Steel Dragon Tools 811A

- For use on RIDGID® Model 1215, 1233, 300, 300 Compact, 535, 535A and 1822 Machines.

- For use on Steel Dragon Tools Model 300 and 300C Machines.

- Replaces Part Number: 97065

Steel Dragon Tools 815A

- For use on RIDGID® Model 300, 300A, 500, 500A, 535, 535A, 800, 801, 802, and 1822 Machines.

- For use on Steel Dragon Tools Model 300 and 300C Machines.

- Replaces Part Number: 97075

Steel Dragon Tools 711

- For use on RIDGID® Model 1224 Machines.

- For use on Steel Dragon Tools Model 1224 Machines.

- Replaces Part Number: 26132

Steel Dragon Tools 714

- For use on RIDGID® Model 1224 Machines.

- For use on Steel Dragon Tools Model 1224 Machines.

- Replaces Part Number: 26152

Steel Dragon Tools 12R

- Steel Dragon Tools manufacturers a full line of 12R die heads. All Steel Dragon Tools die heads thread in the right-hand direction and come with one set of corresponding dies.

- For use with RIDGID® 12R Manual Pipe Threaders and RIDGID® Model 700 Power Drive.

- For use with Steel Dragon Tools 12R Manual Pipe Threaders and Steel Dragon Tools Model 700 Power Drive.

- Replaces Part Numbers: 37390, 37395, 37400, 37405, 37410, 37415

Steel Dragon Tools 11R

- Steel Dragon Tools manufacturers a full line of 11R die heads. All Steel Dragon Tools die heads thread in the right-hand direction and come with one set of corresponding dies.

- For use with RIDGID® 12R Manual Pipe Threaders, RIDGID® Model 600 Power Drive and 700 Power Drive (with adapters).

- For use with Steel Dragon Tools 12R Manual Pipe Threaders, Steel Dragon Tools Model 600 Power drive and Model 700 Power Drive (with adapters).

- Replaces Part Numbers: 20928, 20948, 37110, 37115, 37120, 37125,

Steel Dragon Tools 70131

- Steel Dragon Tools 70131 die head will fit the Wheeler-Rex® 7991 Pipe Threading Machine.

- For use on Wheeler-Rex® Model 7991 Machines.

- For use on Steel Dragon Tools Model 7991 Machines.

- Replaces Part Number: 70131

For more information on the Steel Dragon Tools die heads, click here. For more information on Steel Dragon Tools pipe threading machines, click here.

For more information about Steel Dragon Tools please call contact Customer Service at 734-224-7112 or by e-mail here.

The full line of Steel Dragon Tools are available for purchase from Craig’s Affordable Tools or Toolz Unlimited.

RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

Pipe Abbreviations

As with any profession, there can be lots of arcane abbreviations and jargon – pipe threading is no different. Steel Dragon Tools is committed to educating customers and helping them make informed decisions. Buying a new pipe threader from Steel Dragon Tools may have been the easy part, but trying to figure pipe nomenclature can be downright confusing. For anyone new to the industry, or for veterans looking for a quick refresher, here is how to make sense of pipe nomenclature.

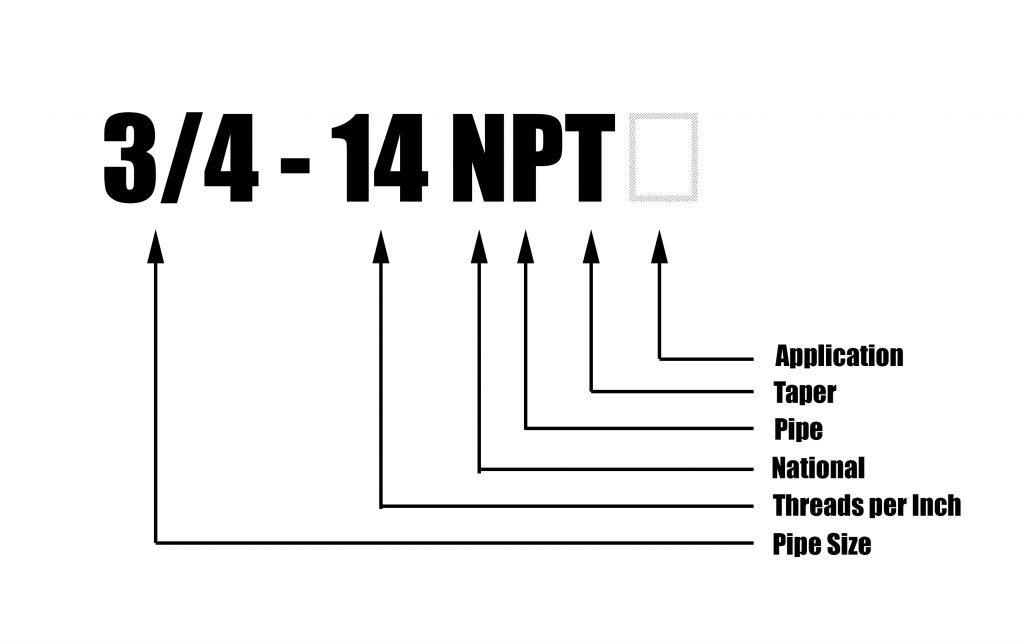

American National Standard Pipe Thread standards are always represented as a string of numbers and letters. Pipe nomenclature will look like this: 3/4 – 14 NPTG. All numbers and letters stand for something and are important to understand the pipe size, the threads per inch, and how the pipe will be used. The first number (3/4) refers to the pipe’s nominal size or outside diameter. The second number (14) will give the threads per inch. The string of letters will describe the threading standard (N stands for National), the type of material being threaded (P stands for Pipe), the thread type (T stands for tapered), and the pipe’s intended use (G stands for gas). All pipe nomenclature must have four letters. Without the fourth letter the use of the pipe and the proper threading procedure cannot be determined.

A – Aeronautical

C – Coupling

F – Fuel

G – Gas

H – Hose

I – Intermediate

L – Loose

N – National

P – Pipe

R – Railing

S – Straight

T – Tapered

Steel Dragon Tools manufactures a variety of different pipe dies and die heads for use on the pipe material listed above. For more information on Steel Dragon Tools pipe threading machines, pipe dies, or die heads please click here or contact customer service here or by phone at 734-224-7112.

Steel Dragon Tools pipe dies are available for purchase from AffordableTool.com and ToolzUnlimited.com.

Pipe Threading Tips

When threading pipe with a Steel Dragon Tools die head, or any die head for that matter, it is important to remember that the scale on the top of the die head i s for reference only. The scale is used to get as close as possible to the correct threading size but it is up to the operator to test the die head, dies, and pipe.

s for reference only. The scale is used to get as close as possible to the correct threading size but it is up to the operator to test the die head, dies, and pipe.

Start by setting the die head to the desired threading capacity. Thread a sample piece of pipe and test the pipe with a c orresponding fitting. A properly threaded piece of pipe will make one and a half to two full turns within the fitting before meeting resistance. A pipe that does not make one and a half to two full turns has threads that were cut too shallow. Shallow threads will not allow the pipe and the fitting to seal properly. A pipe that turns more than two full rotations in the fitting has threads that were cut too deep. A pipe with threads that are too deep may bottom out in the fitting, preventing the pipe and fitting from being tightened.

orresponding fitting. A properly threaded piece of pipe will make one and a half to two full turns within the fitting before meeting resistance. A pipe that does not make one and a half to two full turns has threads that were cut too shallow. Shallow threads will not allow the pipe and the fitting to seal properly. A pipe that turns more than two full rotations in the fitting has threads that were cut too deep. A pipe with threads that are too deep may bottom out in the fitting, preventing the pipe and fitting from being tightened.

Pipe threading is not an exact science, it will take a little finesse and patience to successfully thread pipe and it is a good idea to test the threaded pipe on a regular basis. It is also important to remember that in most cases a sealant will be used on the pipe and fitting to prevent leaks. Using a sealant will allow the operator a bit of leeway when threading pipe.

The pipes themselves can also cause problems during threading. Pipes may not be true to their stated measurements. For example, a 1-inch pipe may be slightly smaller at 15/16 inches in diameter or slightly larger at 1-1/16 inches in diameter. The pipe may also be metric. A 25-millimeter pipe is slightly smaller than a 1-inch pipe but can look identical to the naked eye. Pipe variance must also be considered. Defects in the pipe from the manufacturing process can result in the pipe not being uniform from one end to the other. A pipe might measure 1 in. at the end, bow out to 1-1/16 in. at the middle before returning to 1 in. at the other end. It is always a good idea to periodically test the threaded pipe with a fitting to ensure a tight seal.

More information on Steel Dragon Tools die heads and dies can be found by following the links or calling customer service at 734-224-7112.

Steel Dragon Tools die heads and dies are available for purchase from Craig’s Affordable Tools or Toolz Unlimited.

Best Practices to Ensure High-Quality Products

Steel Dragon Tools has built a reputation manufacturing quality tools and machines while pricing them to beat the competition. Setting forth and following best practices ensures that every product from Steel Dragon Tools meets or exceeds customer expectations and any applicable regulations. Steel Dragon Tools best practices include:

- All Steel Dragon Tools are CE Approved and government tested.

- An on-staff master technician inspects all Steel Dragon Tools to ensure top-of-the-line performance.

- Live, on-site customer service representatives provide valuable product knowledge. Customer service representatives are available to answer questions or offer technical

assistance on Steel Dragon Tools. Customer service representatives can be reached Monday through Friday, 8:00 a.m. to 6:00 p.m. EST at 734-224-7112. - All products manufactured by Steel Dragon Tools are backed by a one year warranty against manufacturer defects.

For more information on Steel Dragon Tools contact customer service here or by phone at 734-224-7112.

Steel Dragon Tools are available for purchase from AffordableTool.com and ToolzUnlimited.com.

Different Types of Pipe

Steel Dragon Tools pipe threading machines can cut, thread, and ream a variety of different types of pipe with the right die head and dies. Some of the different types of pipe available on the market includes black iron, galvanized steel, stainless steel, copper, and plastic. Each pipe material has different uses and qualities.

Steel Dragon Tools pipe threading machines can cut, thread, and ream a variety of different types of pipe with the right die head and dies. Some of the different types of pipe available on the market includes black iron, galvanized steel, stainless steel, copper, and plastic. Each pipe material has different uses and qualities.

Black iron pipe is made from mild steel. Black iron pipe is susceptible to corrosion when exposed to alkaline or acidic water. Black iron pipe is typically used for low-pressure and low-heat applications with gas or steam but is not suitable for potable water.

Cast iron pipe is manufactured with molds and is mostly used for sewage and waste removal. Cast iron pipe will corrode when in contact with carbonic or sulfuric acids. Cast iron pipe can be found in the sewage systems of many homes due to its durability and longevity. This type of pipe is popular for use in waste removal before of its thickness. The pipe’s density helps to muffle the sound of water and waste moving through it, resulting in a quieter home.

Galvanized iron pipe, also known as galvanized steel pipe, is steel pipe with a protective zinc coating. The zinc layer prevents rust and corrosion for approximately 40 years. Once the layer of zinc has been worn away, corrosion and deposits of salt and lime will eventually block the pipe. Galvanized pipe was used for potable water delivery but has been replaced with the more resistant copper and easier-to-handle PVC. Thanks to its anti-corrosion properties, durability, and relatively low cost, galvanized pipe is still popular for use outdoors in irrigation or in large construction projects where the amount of copper pipe needed might be cost prohibitive.

Stainless steel pipe is made with different alloys for use across many industries including food, aircraft and aerospace, nuclear energy, military, and medical applications. Stainless steel pipe is highly regarded for its low maintenance, corrosion resistance, hygienic properties, ease of fabrication, durability, and recyclability. Some types of stainless steel pipe are highly acid resistant and are typically found in chemical plants or for use in food processing.

Copper pipe is durable and corrosion resistant. This type of pipe is easy to handle and install but can be expensive. Copper pipe is typically used for potable water delivery and refrigerant lines in air conditioning systems. Copper pipe can also be used for gas delivery systems, both industrial and medical.

Polyvinyl chloride pipe (PVC) is a versatile material that comes in several chemical variations for different uses. This pipe can be used for pressure and non-pressure applications including potable water service, radiant floor heating, drains, waste removal, venting, irrigation, and ice melting. PVC pipe is inexpensive, easy to handle, and resistant to most household chemicals. PVC pipe does have a low resistance to heat and will expand rapidly when heated. PVC also has a lower pressure rating and crush resistance when compared to most metal pipe.

Steel Dragon Tools manufactures a variety of different pipe dies and die heads for use on the pipe material listed above. For more information on Steel Dragon Tools pipe threading machines, pipe dies, or die heads please click here or contact customer service here or by phone at 734-224-7112.

Steel Dragon Tools pipe dies are available for purchase from AffordableTool.com and ToolzUnlimited.com.

Steel Dragon Tools Buys Used Pipe Threading Equipment

Steel Dragon Tools buys used RIDGID® pipe threading equipment ranging from handheld pipe threader die heads, like the 12-R, up to heavy-duty models like the 1224 and 161. Steel Dragon Tools will also buy the various RIDGID® stands, die heads, and associated products.

Used RIDGID® models that Steel Dragon Tools will purchase:

- Machines: 700, 1215, 300, 300C, 1822, 535 (manual or automatic, all three generations), 1224

- Hog Heads: 141, 161

- Stands: 1206 (300 stand), 450, 460, 460-6(chain vises), 40A (yoke vise)

- Die Heads: 12-R, 811, 811a, 815, 815A, 711, 714

Steel Dragon Tools will also buy accessories that work with the units like drive adapters, pipe cutters, and pipe reamers. Steel Dragon Tools will consider items that are missing components or have been disassembled for purchase as parts units.

Selling used equipment is a great way to clean up the shop and make extra money at the same time. For more information about selling used equipment, please contact us by phone at 734-224-7112 or by e-mail here.

Replacing Dies In A Die Head

Replacing or installing new dies in the Steel Dragon Tools 811A Die Head is quick and easy. Lay the die head on a stable surface and move the handles to make the scroll inside the die head retract. The scroll holds the dies in place.

Replacing or installing new dies in the Steel Dragon Tools 811A Die Head is quick and easy. Lay the die head on a stable surface and move the handles to make the scroll inside the die head retract. The scroll holds the dies in place.

Once the scroll has retracted, slide the die into the die head. The scroll must be fully retracted to remove or install a die into the die slot. Each die is marked with a number and should slide into the corresponding die slot on the die head.

Push the die into the die slot up to the marked line on the top of the die. Once all four dies have been inserted, move the handle to re-engage the scroll, securing the dies in the die head. Some adjustment on each die may be needed if the scroll will not fully engage.

Wiggling the dies back and forth while moving the handle will usually remedy the problem. Once the dies are firmly in place, reinstall the die head onto the pipe threading machine.

Having multiple die heads with

different-sized dies can reduce work stoppage. Utilizing two die heads with different sets of dies will reduce the work load from switching outs dies when threading a variety of pipe sizes and materials. Simply remove the die head from the machine, install the second die head with a different die set, and continue threading pipe.

Steel Dragon Tools dies and die heads are interchangeable with compatible dies and die heads from a variety of manufacturers. Steel Dragon Tools die heads will fit compatible machines and will accept compatible dies. Steel Dragon Tools dies will fit compatible die heads as well.

For more information on Steel Dragon Tools dies and die heads, please contact customer service by e-mail or by phone at 734-224-7112.

The full line of Steel Dragon Tools dies and die heads are available for purchase from Craig’s Affordable Tools or Toolz Unlimited.

The Common Traits of High-Performance Threading Oil

One of the most important elements when threading pipe, manually or with a machine, is the use of high-performance threading oil. High-performance threading oil is critical to producing straight and sharp threads when threading pipe. High-quality, professional-grade pipe threading oil from Steel Dragon Tools will facilitate perfect pipe threads every time.

Not all pipe threading oil is created equal. High-performance threading oil has four common characteristics:

1. LUBRICITY. The oil must have high lubricity to minimize load and reduce friction. Threading oil with high lubricity will reduce the friction between the dies and the material being threaded. Threading oil chemically bonds to the threaded surface and transforms into a metal film as dies cut away material. This metal film lowers the coefficient of friction and the load is reduced, resulting in threads that are straight and sharp.

2. HEAT ABSORBPSTION. Threading oil must absorb heat and immediately conduct it away from the threads. Excessive heat at the cutting surface leads to premature wear of the dies, metal chips welded on to the cutting edge of the dies, and torn, disfigured, or wavy threads.

3. ADHESION. Threading oil should cling to the pipe surface even in extreme temperatures. Oil with the proper viscosity will stick to the surface of the pipe during the threading process. This oil will transform into a metal film, reducing friction and absorbing heat as the pipe is threaded. The lowered friction and cooler temperature will result in straight and sharp threads.

4. CONSISTENCY. The viscosity and effectiveness of the oil must remain consistent throughout its operating life. High-quality threading oil will resist oxidation and will not have any volatile c ompounds that can evaporate. The performance of the oil should remain effective throughout its life cycle.

ompounds that can evaporate. The performance of the oil should remain effective throughout its life cycle.

With proper care, high-quality threading oil will never need to be changed. Threading oil only needs to be changed if the oil is contaminated with solvents, other oils, dirt, or grit. New oil should be added as needed to maintain the proper level in the oil sump of the pipe threading machine or the oiling bucket. Oil loss while threading pipe is common since  the oil will stick to the threaded material.

the oil will stick to the threaded material.

High-performance threading oil from Steel Dragon Tools has high lubricity, and will absorb and dissipate heat immediately. Steel Dragon Tool threading oil easily clings to threading surfaces, and maintains a consistent viscosity throughout its operating life. Steel Dragon Tools threading oil does not contain PCBs, heavy metals, chlorine, or other halogens.

To purchase the Steel Dragon Tools high-performance threading oil, visit Craig’s Affordable Tools or Toolz Unlimited.

For more information on the Steel Dragon Tools high-performance threading oil call 734-224-7112 or e-mail customerservice@steeldragontools.com.

Steel Dragon Tools Pipe Threading Machine Die Heads fit RIDGID® Dies

Most Steel Dragon Tools pipe threading machine die heads will fit RIDGID® pipe threading dies. Steel Dragon Tools die heads will accept either SDT or RIDGID® brand d ies.

ies.

RIDGID® dies are available from a wide range of RIDGID® dealers. If there isn’t time to order new Steel Dragon Tools dies, simply purchase RIDGID® brand dies loca lly and finish the job.

lly and finish the job.

Steel Dragon Tools manufacturers several popular models of die heads including the 811A and 815A Universal, Self-Opening Die Heads for Models 300, 300A, 500, 500A, 535, 535A, 800, 801, 802, and 1822 pipe threading machines. Universal, Self-Opening 711 and 714 Die Heads are available for Model 1224 pipe threading machines.

Steel Dragon Tools also manufacturers dies and die heads, like the 11-R and 12-R , for manual pipe threading machines. Stee l Dragon Tools 11-R and 12-R Die Heads will work with compatible Steel Dragon Tools and RIDGID® hand-held power drive pipe threaders. Steel Dragon Tools 11-R and 12-R die heads can also be used with certain manual ratchet-style pipe threaders.

l Dragon Tools 11-R and 12-R Die Heads will work with compatible Steel Dragon Tools and RIDGID® hand-held power drive pipe threaders. Steel Dragon Tools 11-R and 12-R die heads can also be used with certain manual ratchet-style pipe threaders.

To purchase Steel Dragon Tools dies and die heads, please visit Craig’s Affordable Tools or Toolz Unlimited.

Steel Dragon Tools is not an authorized distributor of RIDGID® and/or Ridge products. RIDGID® Marks are trademarks of RIDGID, Inc and are used for product identification purposes only.

No RIDGID, Inc., Emerson Electric Co., or Ridge Tool Company warranties apply to reconditioned and/or refurbished products. The original manufacturer’s certifications no longer apply to reconditioned and/or refurbished product.

RIDGID® Marks are trademarks of RIDGID, Inc. and are used for product identification purposes only. Steel Dragon Tools® offers a one (1) year warranty against manufacturer defects on all Reconditioned RIDGID® machines.