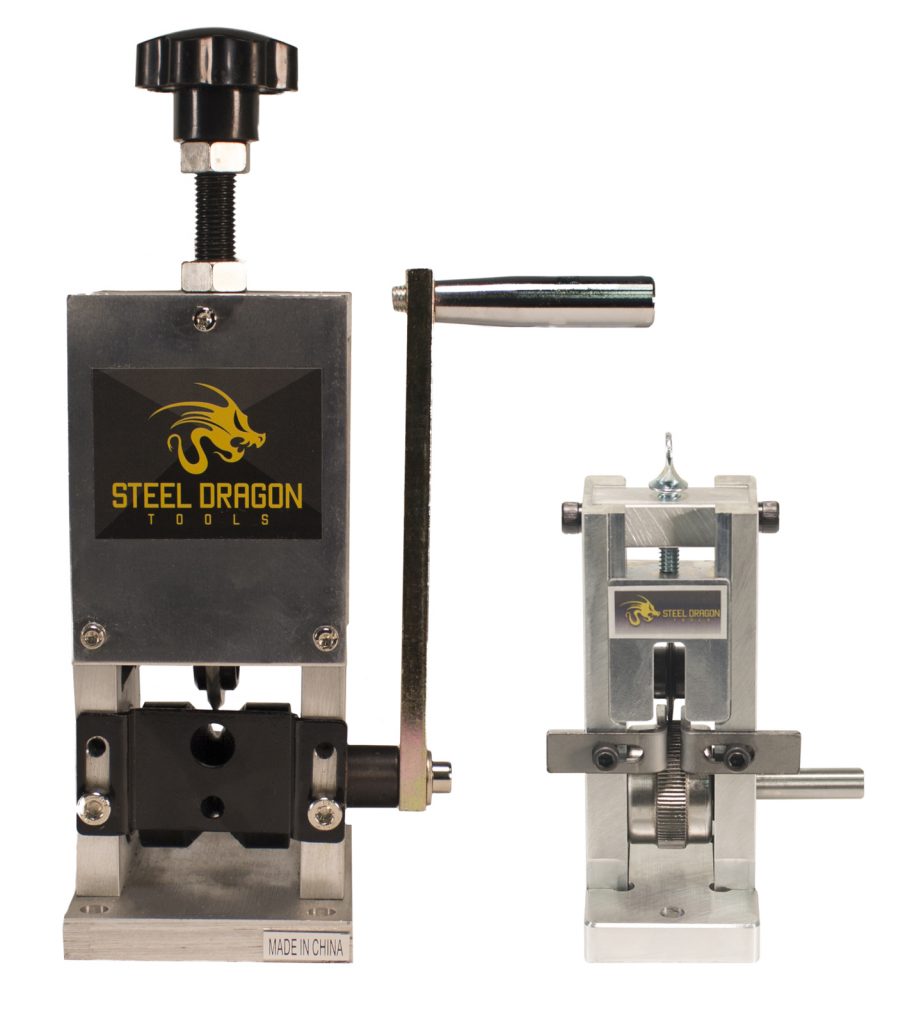

Wire Strippers – WRA 10 vs WRA 15

Steel Dragon Tools offers several different models of wire strippers. The two entry level options are the WRA10 and the WRA15. Both models can be operated manually with a hand crank or automatically with a drill. The WRA10 and WRA15 are an ideal entry point for anyone looking to strip wire and increase recycling payouts on scrap metal.

The WRA10 is small, at 6-inches in height it is almost pocket size. But behind the diminutive size is an easy to operate machine that will quickly and cleanly strip up to 450 inches of wire per minute when connected to a drill. The WRA10 will strip wire up to roughly 1/2-inch in diameter.

The WRA15 is the more traditional benchtop model. It boasts a larger size and wire-stripping capability. Standing at 12-1/2-inches in height it will also strip up to 450 inches of wire per minute when connected to a drill. The WRA15 will strip wire up to roughly 1-inch in diameter.

Set Up is Key

Set up is the most important step to successfully strip wire. Following these tips will help make the wire stripping process quick and easy. These tips apply to both the WRA10 and WRA15.

- Secure the wire stripper to the benchtop. Screwing or bolting the wire stripper to the bench will stop it from moving during the stripping process, freeing the hands to feed the wire and operate the drill at the same time.

- Separate wire by size, set machine to strip that size, and then strip all of that wire at once. Getting the wire stripper keyed in to quickly strip the wire requires careful set up. Strip one size at a time before moving on to avoid wasting time readjusting between each piece.

- Do not run the drill at full speed. A common mistake is to run the drill as fast as possible. Typically, this will result in a wire that isn’t completely stripped as well as reducing the life of the cutting wheel.

- Run the drill slowly and at an even pace. The same applies when using the hand crank.

- Run the wire through twice. The WRA10 and WRA15 only have one cutting wheel. Run the wire through once and then rotate it 180 degrees before running it through again. Two cuts in the casing will make stripping the wire much easier.

- Straighten the wire and cut it into manageable pieces between 12-inches and 24-inches in length. A straight piece of wire has little chance of bunching up and clogging the machine. A short piece of wire will run through the machine quickly, especially if the operator wants to run it through twice.

- Running long pieces of wire can pose a safety hazard. This warning applies to the larger machines but the principle is still the same. When running long pieces of wire can be dangerous as the wire may become wrapped around the operator or other nearby objects. The operator or these objects can then be pulled toward the wire stripper if enough force is being generated.

For more information on Steel Dragon Tools call 734-224-7112 or e-mail customerservice@steeldragontools.com.

Steel Dragon Tools products are available for purchase from Affordable Tool and Toolz Unlimited. Steel Dragon Tools products can also be purchased at major online retailers like Amazon, Sears, and Walmart.

Wire Stripping Machines

Steel Dragon Tools manufactures a range of wire stripping machines – from the hand-held, drill-driven wire strippers to industrial-sized, fully automatic wire strippers, plus several models in between. Steel Dragon Tools has five different automatic wire stripping machine models – WRA10, WRA15, WRA20, WRA35, and WRA40 – and two manual wire stripping machines – WRM25, WRM33, and WRM35.

Steel Dragon Tools manufactures a range of wire stripping machines – from the hand-held, drill-driven wire strippers to industrial-sized, fully automatic wire strippers, plus several models in between. Steel Dragon Tools has five different automatic wire stripping machine models – WRA10, WRA15, WRA20, WRA35, and WRA40 – and two manual wire stripping machines – WRM25, WRM33, and WRM35.

Wire stripping machines are a must-have for contractors, demolitions companies, dedicated DIYers, and scrappers. Stripping wire will result in higher return prices for wire at recycling centers. Steel Dragon Tools wire stripping machines can pay for themselves within a few hours depending on material and current scrap prices.

The WRM33 and WRM35 are benchtop wire strippers with m anual operation. The WRM33 and WRM35 will strip a variety of wire sizes including Romex. These machines are powered by an attached hand crank. The WRM33 and WRM35 are light weight and very portable. The blades are fully guarded to ensure complete safety during operation.

The WRA10 and WRA15 are benchtop wire strippers. These models are drill-driven and are ideal for the occasional wire stripping. The WRA15 can also be used manually with an included hand crank handle.

The WRA20 and WRA35 are larger, benchtop models with automatic operation. Both models feature built-in 120-volt motors. The WRA20 and WRA35 are portable for easy transportation to the job site. Both machines will strip a variety of wire sizes, including round and flat stock. The WRA35 also includes a hand crank for manual use.

The WRA40 is the largest wiring stripping machine from Steel Dragon Tools. The WRA40 is a floor model that will strip up to 125 feet of wire per minute. This machine will cut two different sized wire at the same time from 34 AWG up to 1-1/2-inch wire. The WRA40 is powered by an American-made Leeson m otor. This machine is ideal for demolition companies, recycling companies, contractors, and scrappers. Stripped wire will fetch a higher price at the recycling facility. The WRA40 is also sold with a heavy-duty foot pedal.

otor. This machine is ideal for demolition companies, recycling companies, contractors, and scrappers. Stripped wire will fetch a higher price at the recycling facility. The WRA40 is also sold with a heavy-duty foot pedal.

Steel Dragon Tools offers replacement cutting wheels for the full line of wire stripping machines. Replacement motor parts are also available for the WRA40.

For more information on Steel Dragon Tools wire stripping machines and replacement parts, click here.

To purchase any Steel Dragon Tools wire stripping machines visit AffordableTool.com and ToolzUnlimited.com.

For more information on any of the magnet tools made by Steel Dragon Tools, please contact customer service by e-mail here or by phone at: 734-224-7112.